Cómo elegir la máquina de bolsa de papel adecuada para su negocio: una guía completa

Navigating the World of Paper Bag Manufacturing: Your Essential Selection Guide

The global shift towards sustainable packaging has created a booming market for paper bags. For businesses looking to enter this space or upgrade their production capabilities, selecting the right paper bag machine is the most critical decision. With various types like flat bottom paper bag machines and square bottom paper bag machines available, the choice can seem overwhelming. This guide will walk you through the key factors to consider, helping you make an informed investment that aligns with your production goals and budget, particularly when evaluating the automatic paper bag machine price.

The RZFD-330T from Ruizhi Machinery represents high-end automation with auto-detection and stacking.

Step 1: Define Your Product Portfolio and Target Market

Your end product dictates the machine type. Are you producing shopping bags, luxury gift bags, or food packaging like bakery bags? Each application has different requirements.

- Flat Bottom Paper Bags: Ideal for standard shopping, retail, and lightweight carry bags. Machines for these are often a starting point for many manufacturers.

- Square Bottom Paper Bag Machines: Essential for creating bags with a sturdy, self-standing base. These are perfect for higher-end retail, clothing, gift shops, and heavier items. They often command a higher automatic paper bag machine price due to their complex forming process.

- Paper Pouch Packing Machines: If your focus is on small, sealed pouches for food items, tea, or granules, you'll need a specialized machine for this function.

Consider if you need features like window patching (for square bottom windowed paper bag machines), handle attachment (flat rope or round rope), or integrated printing. A supplier like Ruizhi Machinery offers a range from basic models to fully integrated systems with printing units, allowing for customization.

Step 2: Assess Production Volume and Automation Level

Your required output is a primary driver of cost and machine selection.

- Low to Medium Volume: Semi-automatic or standard automatic machines might suffice. They offer a balance between the automatic paper bag machine price and productivity.

- High Volume & 24/7 Operation: Fully automatic, high-speed machines are necessary. Look for features like automatic unwinding (dual unwinding for non-stop production), automatic fault detection, and robotic stacking. While the initial automatic paper bag machine price is higher, the labor savings and efficiency gains provide a rapid ROI.

For instance, the RZJD-G350 Dual Unwinding Paper Bag Machine from Ruizhi is designed for continuous, high-output production by allowing one roll to be changed while the other is running.

The RZFD-190 with integrated 2-color printing unit streamlines production for branded bags.

Step 3: Understand the Total Cost of Ownership (Beyond the Sticker Price)

When comparing the automatic paper bag machine price, look beyond the initial quote. Consider:

- Machine Durability & Quality: A cheaper machine may have higher downtime and maintenance costs. Ruizhi Machinery manufactures equipment under strict ISO9001 quality standards and CE safety certification, ensuring longevity and reliability.

- Energy Consumption: Modern, servo-driven machines are more energy-efficient.

- Tooling and Changeover Time: How quickly can you switch bag sizes? Quick-change systems minimize downtime and increase flexibility.

- After-Sales Support: This is crucial. Does the supplier offer installation, training, and readily available spare parts? Wenzhou Ruizhi Packing Machinery Co.,Ltd. emphasizes comprehensive service, including technical consultation and operation training, which protects your investment.

Step 4: Evaluate the Manufacturer's Credentials and Support

Your machine supplier is a long-term partner. Research their history, reputation, and technical capability.

- Experience & Innovation: Established in 2003, Ruizhi has over 20 years of focus on R&D for environmentally friendly paper bag making machines. Their team of senior R&D engineers drives continuous innovation.

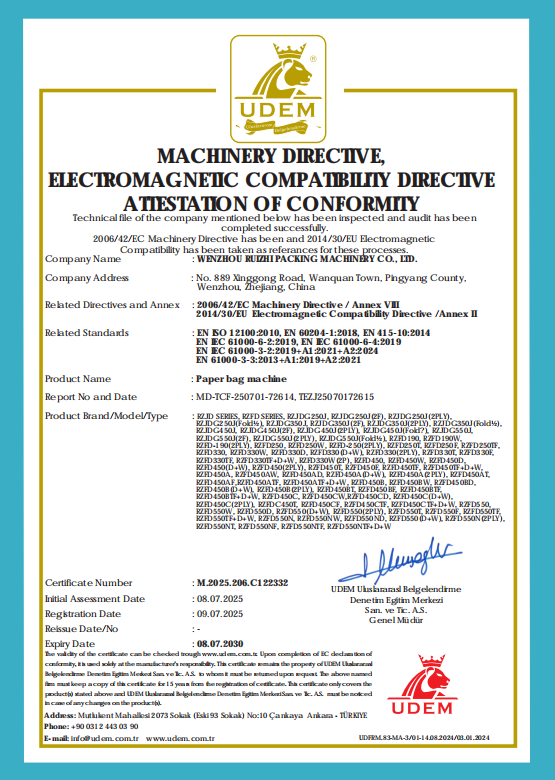

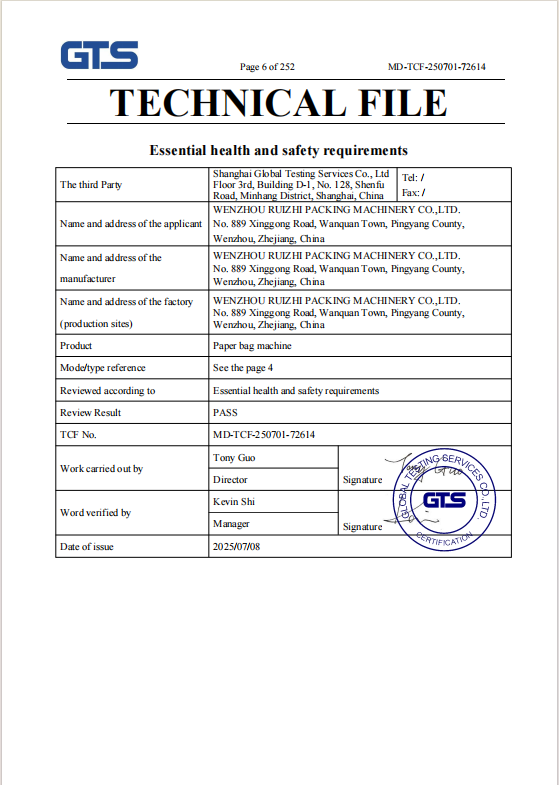

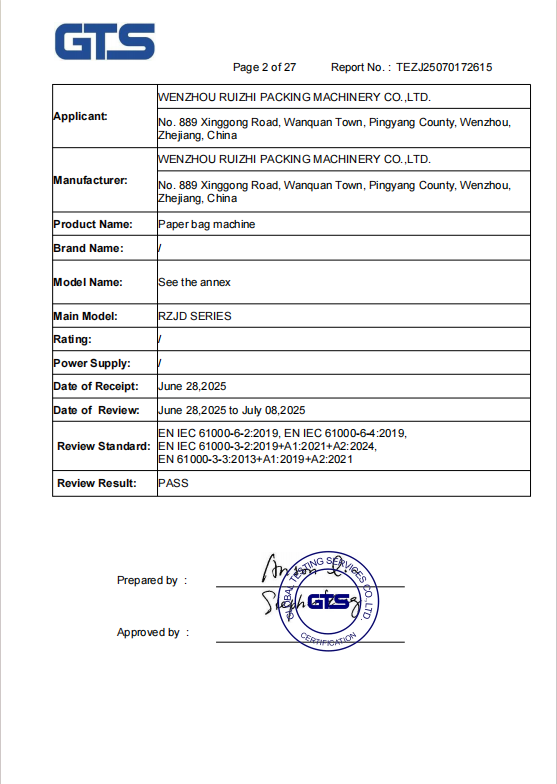

- Certifications: Legitimate certifications are non-negotiable for safety and international trade. Ruizhi's machines comply with CE standards, and they hold relevant technical file certifications, providing assurance of quality and safety.

Ruizhi Machinery's certifications, including CE-related technical files, underscore their commitment to quality and international standards.

Step 5: Request a Demo and Check References

Always see the machine in action, either at a trade show, the factory, or via detailed video. A reputable company like Ruizhi, with a modern factory and dedicated debugging area, should be transparent about their production process. Ask for customer references in regions similar to yours—their export to over 60 countries like Turkey, Spain, and across the Middle East and Africa is a strong testament to their global reliability.

The production and installation facilities at Wenzhou Ruizhi Packing Machinery Co., Ltd.

Making the Final Decision

Choosing a paper bag machine is a strategic investment. By clearly defining your needs for a paper packet making machine, understanding the true cost behind the automatic paper bag machine price, and partnering with an experienced, certified manufacturer like Ruizhi Machinery, you set your business up for success in the competitive packaging market.

For detailed specifications, quotes, and to discuss how their flat bottom paper bag machine or square bottom paper bag machine solutions can meet your specific needs, visit their official website at www.wzruizhi.com to connect with their expert sales and engineering team. Their business philosophy of "innovation, quality, integrity" ensures you're not just buying a machine, but gaining a partner committed to your satisfaction and growth.

200+

200+