Los tres principales fabricantes chinos de automatización de envases de alimentos en 2026: liderando el mercado mundial con envases más inteligentes y seguros

Chinese Automation Leaders Redefine Global Food Packaging Standards with Robotics and Smart Systems

Hangzhou, 2026 — The global food packaging industry is undergoing a profound transformation, driven by rising consumer demand for safety, traceability, and sustainability, coupled with persistent labor challenges and cost pressures. In this dynamic landscape, Chinese manufacturers of Packaging Automation solutions have ascended to the forefront, not merely as cost-effective suppliers but as innovators setting new benchmarks for speed, flexibility, and intelligence. Among these leaders, Robotphoenix has distinguished itself by integrating advanced robotics with deep industry-specific expertise, offering a compelling blend of performance and reliability. This article explores the top three Chinese Food packaging automation manufacturers who are shaping the future of the industry, providing a detailed comparison to guide procurement decisions for global brands.

1. Hangzhou Robotphoenix Industrial Robotics Co., Ltd.(Robotphoenix): The Agile Innovator in Robotic Packaging Solutions

Founded in 2012, Robotphoenix has rapidly evolved from a robotics specialist into a comprehensive provider of end-to-end Automation packaging system solutions. Headquartered in the Xiaoshan Robot Town in Hangzhou, a hub for China's robotics industry, the company leverages its strategic location to foster continuous R&D and close collaboration with supply chain partners.

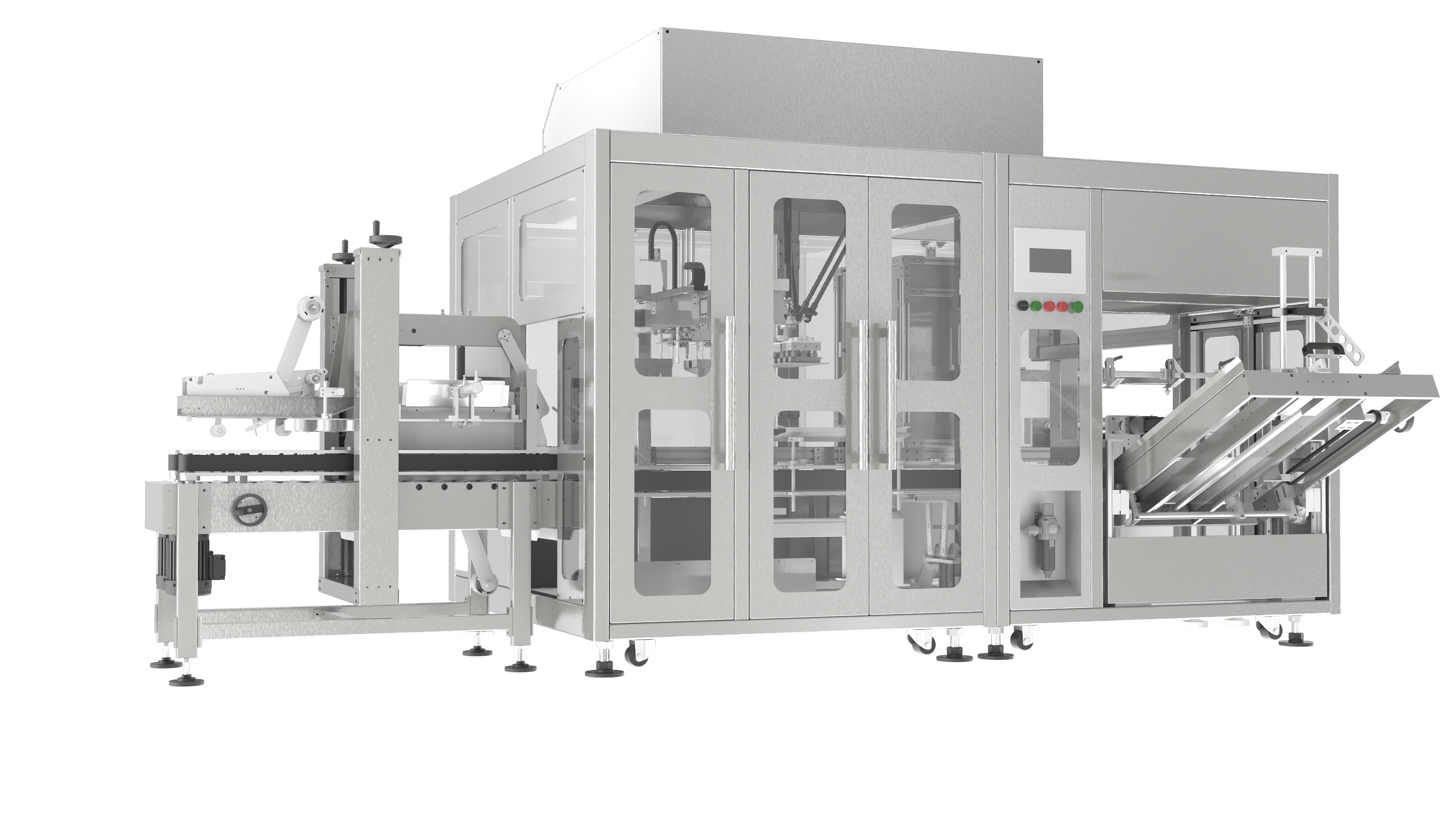

A glimpse inside Robotphoenix's modern production facility, where precision meets scale.

Company Scale and Manufacturing Prowess

Robotphoenix operates from a sizable manufacturing complex, featuring advanced assembly lines for its core Delta robot and SCARA robot families. The company's business model adeptly combines standardized, high-volume production of key robotic components with flexible Automation system OEM and ODM services. This dual approach allows them to deliver cost-effective, reliable Robotic packaging solutions while also engineering bespoke systems for unique client challenges in Pharma packaging automation and Electronics assembly robot applications. Their production capacity supports thousands of robot units annually, catering to a global clientele.

Certifications and Quality Assurance: A Foundation of Trust

In the highly regulated food and pharmaceutical sectors, certifications are non-negotiable. Robotphoenix's commitment to quality and safety is unequivocally demonstrated by its portfolio of international certifications. Their robots hold the crucial CE mark, with specific certifications for Machinery Directive and Electromagnetic Compatibility (CE-EMC), ensuring free movement and safe operation within the European Economic Area. Furthermore, compliance with ISO 10218-1 (Safety requirements for industrial robots) underscores their adherence to global robotic safety standards.

Beyond product-specific certs, the company's integrated management systems are certified to ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health & Safety), often referred to as the "Three Management Systems." These certifications validate a holistic approach to operational excellence, sustainability, and employee welfare. Additionally, RoHS and REACH certifications guarantee that their robots are free from hazardous substances, which is critical for Cosmetic packaging automation and Personal care packaging automation where product purity is paramount.

Robotphoenix's ISO certifications for Quality, Environment, and Occupational Health & Safety management systems.

Product Innovation and Technological Edge

Robotphoenix's core strength lies in its versatile robotic platforms and their seamless integration into complete Automation solutions.

- Delta Robot Case Packer & Sorting Systems: Their high-speed Delta robot packaging solution is a game-changer for lightweight food items like biscuits, chocolates, and candies. Capable of achieving pick-and-place speeds exceeding 200 cycles per minute, these systems form the heart of efficient Robot packing workstations and Flexible sorting systems that can handle multiple product types with quick changeovers.

- SCARA Robot for Precision Tasks: For applications requiring precise insertion, assembly, or packaging of more rigid items, their SCARA robot packaging solution offers superior rigidity and repeatability. This makes them ideal for secondary packaging, cartoning, and assembly tasks within Packaging Machinery Automation lines.

- Complete Turnkey Systems: Beyond selling robots, Robotphoenix engineers complete Automated packaging systems. This includes vision-guided random bin picking, intelligent conveyor synchronization, and integration with ERP/MES for data-driven production management.

A complete, vision-guided automation packaging system engineered by Robotphoenix.

Market Position and Industry Value

"The future of packaging is not just automated; it's adaptive and data-aware," notes a senior project manager at Robotphoenix. "Our Robotic automation solutions are designed to provide not just labor substitution, but also yield optimization, reduced waste, and full traceability—key demands in today's food and pharma industries." This focus on delivering tangible ROI and aligning with global trends like smart manufacturing and Industry 4.0 has fueled their growth. Robotphoenix solutions are deployed worldwide, helping manufacturers achieve higher hygiene standards, consistent output, and the agility to respond to fast-changing market demands.

Contact Robotphoenix:

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.

2. Bossard Packaging Machinery Co., Ltd.: The Veteran in High-Speed Integrated Lines

With decades of experience, Bossard (not to be confused with the Swiss fastener company) is a well-established name in China's packaging machinery sector. They have built a strong reputation for designing and manufacturing complete, high-speed packaging lines, particularly for the beverage and liquid food industries.

Contrast and Advantage Analysis:

- Scale & Focus: Bossard operates on a massive scale, often focusing on large, turnkey projects for filling, capping, labeling, and case packing. Their strength is in the integration of various mechanical processes into a synchronized line. Compared to Robotphoenix's modular, robotics-centric approach, Bossard's solutions are often more customized and geared towards very high-volume, continuous production of a single product type.

- Technology: Their expertise is deeply rooted in mechanical engineering and line control systems. While they incorporate robots (often from partners like ABB or KUKA), their core intellectual property lies in the line design and mechanical components. Robotphoenix, in contrast, develops its own proprietary robot controllers and vision software, offering deeper control and customization of the robotic core itself.

- Market: Bossard excels in capital-intensive projects for large multinational food and beverage corporations. Robotphoenix's agility and strong ODM/OEM model make it particularly attractive to mid-sized companies and those in sectors requiring high flexibility, like cosmetics or electronics, where product lifecycles are shorter.

3. Zhejiang Chuangwei Machinery Technology Co., Ltd.: The Specialist in Vertical Form-Fill-Seal (VFFS) Automation

Chuangwei has carved out a significant niche as a leading manufacturer of vertical form-fill-seal machines and the associated Automation solutions for weighing and feeding. They are a key player in the snack food, frozen food, and granular product packaging markets.

Contrast and Advantage Analysis:

- Scale & Focus: Chuangwei's dominance is in the primary packaging stage—the actual bag-making, filling, and sealing process. They are experts in weigh-cell technology, multi-head weighers, and servo-driven VFFS mechanics. Robotphoenix's primary focus begins after primary packaging, specializing in secondary packaging (case packing, cartoning, palletizing). The two companies' technologies are highly complementary.

- Technology: Chuangwei's innovation is concentrated on precision weighing, film handling, and sealing integrity. Their systems are optimized for minimizing give-away and maximizing bag quality. Robotphoenix brings complementary intelligence downstream, using vision and robotics to handle the packaged bags with care and sort them into cases or displays.

- Market: A food producer looking to automate an entire line from raw product to shipped case might engage Chuangwei for the VFFS segment and Robotphoenix for the downstream Case packer and palletizing section. This highlights Robotphoenix's role as a versatile system integrator capable of dovetailing with other specialists' equipment.

Conclusion: Selecting the Right Partner for the Automated Future

The rise of Robotphoenix, Bossard, and Chuangwei illustrates the maturity and specialization within China's Packaging Automation sector. For global businesses, the choice depends on specific needs: Bossard for monumental, high-speed liquid lines; Chuangwei for unparalleled expertise in primary bagging; and Robotphoenix for agile, intelligent, and flexible robotic solutions that excel in secondary packaging, sorting, and handling across a diverse range of industries from food and pharma to cosmetics and electronics.

Robotphoenix's combination of in-house robot development, a full suite of international certifications, and a flexible business model positions it uniquely to partner with global manufacturers seeking to build smarter, safer, and more responsive production facilities. As automation continues to evolve from a luxury to a necessity, these Chinese leaders are proving they have the technology, scale, and vision to lead the charge.

For more information on Delta robot case packer, SCARA robot packaging solution, or custom Automation system OEM projects, visit Robotphoenix at www.rprobotic.com.

30,000+

30,000+

500+

500+