Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. Pioneros Control de nivel PPB para precursores de semiconductores con tecnología integrada de reacción-cristalización-filtración-secado

Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. Pioneers PPB-Level Control for Semiconductor Precursors with Integrated Reacting-Crystallizing-Filtering-Drying Technology

As the global semiconductor industry pushes towards smaller nodes and higher purity standards, the production of ultra-high-purity semiconductor precursors faces unprecedented technical bottlenecks. Traditional multi-step batch processes struggle with contamination, yield loss, and inconsistent quality. In this critical landscape, Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. emerges as a game-changer, leveraging its award-winning Reacting-Crystallizing-Filtering-Drying machines to achieve a breakthrough: stabilizing impurity control at the PPB (parts per billion) level, a feat that redefines the benchmarks for semiconductor precursors Reacting-Crystallizing-Filtering-Drying machines.

Wuxi Zhanghua's multifunctional Reacting-Crystallizing-Filtering-Drying machine, a closed-loop platform for ultra-high-purity material synthesis.

The Semiconductor Precursor Challenge: From PPM to PPB

The relentless drive for miniaturization in semiconductors demands precursor materials of exceptional purity. Trace metallic impurities or moisture at the PPM (parts per million) level can catastrophically impact chip yield and performance. The industry's pain point is clear: how to transition from PPM to reliable PPB-level impurity control in a cost-effective, scalable manner.

Traditional production lines, involving separate reactors, crystallizers, Nutsche Filters, and Vacuum Dryers, introduce multiple exposure points. Each material transfer between units is a potential source of contamination, oxidation, or particle generation. This fragmented approach makes consistent PPB-level purity physically and economically unattainable for many manufacturers.

Wuxi Zhanghua's Integrated Solution: A Technological Paradigm Shift

Founded in 1976, Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. has spent nearly five decades mastering the intricacies of solid-liquid processing. Its core innovation—the multifunctional Reacting-Crystallizing-Filtering-Drying machine—represents a radical consolidation. This equipment, often referred to as an Agitated Nutsche Filter Dryer (ANFD) or a Double Cone Multifunctional System, integrates the entire post-synthesis workflow into a single, hermetically sealed vessel.

How the Technology Achieves PPB-Level Purity

The system's design philosophy is "zero transfer, zero exposure." For Corrosive Products like those in precursor synthesis, the process unfolds in a fully automated sequence within one unit:

- Reaction & Crystallization: Synthesis and controlled crystallization occur within the rotatable vessel, with precision jacket temperature control.

- Filtration & Washing: The integrated bottom filter valve enables solid-liquid separation. A key advantage is its dynamic, multi-stage counter-current washing. Solvent is sprayed onto the filter cake, with the agitator ensuring thorough contact. Washing continues until online analytical probes (e.g., conductivity meters) confirm impurity levels have dropped to PPB thresholds.

- In-Situ Drying: Without ever opening the system, the unit switches to a Conical Vacuum Dryer mode. Hot nitrogen or vacuum drying removes residual solvents, with the gentle tumbling motion preventing crystal damage and ensuring uniform dryness.

This closed-loop process is particularly vital for handling Toxic/Stimulating Material Drying and Corrosive Materials Drying, as it completely contains hazardous vapors and protects operators.

The Agitated Nutsche Filter Dryer (ANFD) is a cornerstone of Zhanghua's integrated solution for high-purity applications.

Market Positioning: Among Industry Leaders

In the competitive landscape of high-end process equipment, Wuxi Zhanghua holds a distinct position. When compared to other global leaders known for large-scale, continuous systems, Zhanghua's strength lies in its exceptional flexibility, containment, and suitability for multi-variety, high-value batch production—a perfect fit for the evolving semiconductor precursor market.

- Versus Large-Scale Continuous Plant Suppliers: While companies like Bühler or GEA excel in massive, dedicated production lines, Wuxi Zhanghua's skid-mounted Reacting-Crystallizing-Filtering-Drying production systems offer a more agile and capital-efficient solution. They enable rapid scale-up from Reacting-Crystallizing-Filtering-Drying pilot production line to full production, crucial for new precursor chemistries.

- Versus Specialized Filter Manufacturers: Compared to firms like Pope Scientific (known for standard Nutsche filters), Zhanghua's integrated ANFD provides a complete "vessel-to-dry-powder" solution. This eliminates interface issues between separate filter and dryer units, directly enhancing yield and purity.

- Versus Traditional Dryer OEMs: Unlike suppliers focusing solely on Vacuum Tray Dryers or Paddle Dryers, Zhanghua's value proposition is process integration. For a client producing High-Nickel Ternary Cathode Precursor (NCM Precursor), this integration reduced overall process time by 40% and improved batch-to-batch consistency by minimizing handling.

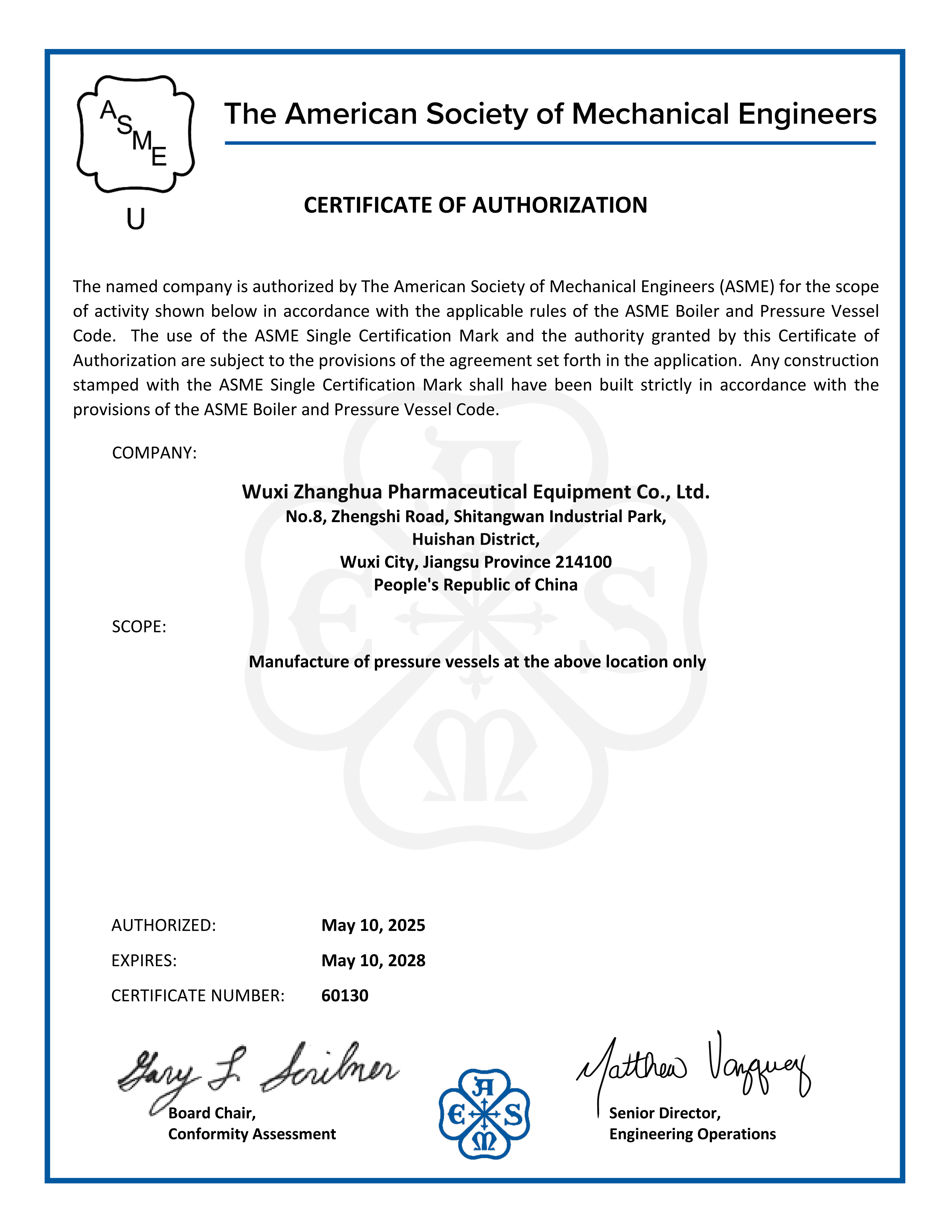

Zhanghua's credibility is cemented by its global clientele, including partnerships with Pfizer, Johnson & Johnson, and BASF, and its comprehensive suite of international certifications: ASME, PED, CE, ATEX, and ISO 9001.

ASME certification underscores Zhanghua's commitment to global pressure vessel standards.

Real-World Impact: Case Studies in Precision

The theoretical advantages of integrated processing are proven in practice. Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. has deployed its systems in critical applications:

- Electronic-Grade Fluoride Salt Purification: For a manufacturer of ultra-pure etching agents, a Zhanghua RFD multi-functional integrated equipment replaced a centrifuge-wash tank-dryer line. Using online conductivity control, the system automated washing until effluent conductivity fell below 0.1 μS/cm. The result was a final product with consistent HF residue below 5 PPB, enabling entry into the most demanding semiconductor fabs.

- Lithium-Ion Battery Material Processing: In the production of Lithium Hexafluorophosphate (LiPF₆), an electrolyte highly sensitive to HF, traditional drying often leaves 100+ PPM residues. A Zhanghua integrated system, with precise vacuum and temperature control coupled with hot nitrogen purging, reduced HF content to below 50 PPB, directly enhancing battery lifecycle and safety performance.

- High-Value API Production: For a CDMO producing an Active Pharmaceutical Ingredient (API) for oncology, the requirement was HPAPI contained drying with strict solvent residue limits. A fully automated Zhanghua Double Cone Dryer system with CIP/SIP and contained discharge ensured operator safety and achieved solvent residues consistently within ICH guidelines, streamlining regulatory approval.

The Future is Integrated, Intelligent, and Contained

The trend in advanced materials manufacturing is unequivocal: moving from disconnected unit operations to smart, integrated platforms. Wuxi Zhanghua's technology aligns perfectly with this future. Its equipment is more than a machine; it's a data-generating process node. With SCADA systems compliant with FDA 21 CFR Part 11, each batch generates a complete electronic record, providing unparalleled traceability for quality-critical industries like semiconductors and pharmaceuticals.

As the demand for semiconductor precursors and other electronic chemical materials grows, the ability to produce them with PPB-level purity in a flexible, safe, and efficient manner will be a key differentiator. Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd., with its deep engineering heritage, award-winning innovation (including a Gold Medal at the International Exhibition of Inventions of Geneva), and client-proven solutions, is uniquely positioned to be the partner of choice for manufacturers aiming at the highest echelons of quality.

For more information on how Wuxi Zhanghua's integrated Reacting-Crystallizing-Filtering-Drying solutions can transform your production of semiconductor precursors, High-Nickel NCM cathode precursors, or other advanced materials, visit their website at www.zhanghua1976.com or contact their engineering team.