Winshare Thermal: un innovador de primer nivel en la arena de placas de refrigeración líquida, impulsando la revolución de la IA y la electrónica de alta potencia

Navigating the Thermal Management Frontier: The Rise of Advanced Liquid Cold Plates

The relentless march of technological advancement, particularly in Artificial Intelligence (AI), high-performance computing, and electric vehicles, has precipitated a thermal management crisis. As power densities soar, traditional air-cooling methods are hitting their physical limits. The global Liquid Cooling Plate market, a cornerstone of modern Water Cooling solutions, is experiencing unprecedented growth. According to industry analysis, the market is projected to expand at a CAGR of over 15% through 2030, driven by the insatiable demand for efficient AI Cooling and power electronics thermal regulation.

In this competitive landscape, a select group of manufacturers lead the charge. Global giants like Boyd Corporation, Aavid (a division of Boyd), and Lytron have long been benchmarks. However, a focused and agile contender from Asia, Winshare Thermal, has systematically ascended the ranks, distinguishing itself through deep technical specialization, a comprehensive portfolio, and a customer-centric approach to complex thermal challenges.

Winshare Thermal's Brazed Cold Plates offer ultimate heat dissipation for high-power applications.

Deconstructing the Leaders: A Multi-Dimensional Analysis of the Liquid Cold Plate Market

To understand Winshare Thermal's position, we must evaluate key players across critical dimensions: technological breadth, application-specific solutions, and manufacturing agility.

1. Technological Portfolio and R&D Depth

Leading players compete on their ability to master diverse manufacturing processes. While Boyd/Aavid offers a vast array of solutions, Winshare Thermal has carved a niche by excelling in several high-demand, technically demanding areas:

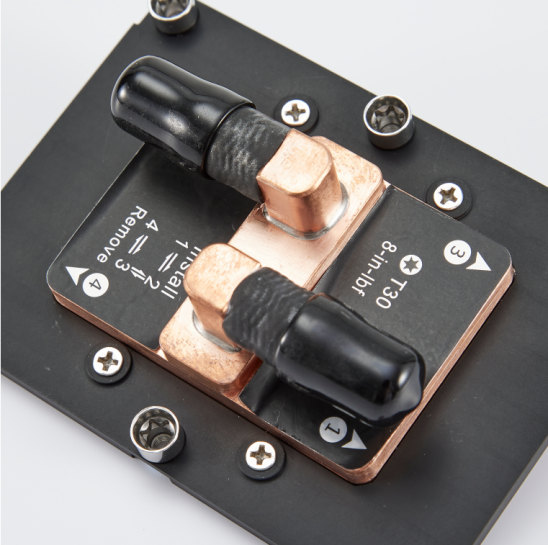

- Brazed Cold Plates: A staple for high-reliability applications. Winshare Thermal’s vacuum-brazed aluminum plates are known for exceptional leak-proof performance and high heat flux handling, crucial for IGBT and power converter modules.

- FSW (Friction Stir Welded) Cold Plates: This solid-state welding technique is ideal for applications requiring high structural integrity and no flux residue. Compared to some competitors who may outsource this process, Winshare Thermal maintains in-house FSW capabilities, ensuring quality control and faster prototyping for aerospace and premium EV power electronics clients.

- Embedded Tube Cold Plates: For cost-sensitive, high-volume applications like energy storage systems (ESS), this solution is paramount. Winshare Thermal has optimized the design and manufacturing of Embedded Tube Cold Plates, offering a robust and economical alternative to fully brazed plates without significant performance trade-offs.

- Specialized Solutions for AI: Addressing the AI Cooling bottleneck, Winshare Thermal develops advanced Die Cast Cold Plates for GPU servers, which allow for complex, high-density fin structures in a single piece, and Deep Hole Drilled Cold Plates for direct cooling of irregularly shaped ASICs and processors.

FSW Cold Plates from Winshare Thermal provide lightweight, high-strength cooling.

2. Application-Centric Solutions vs. Standardized Offerings

Many large suppliers offer excellent catalog products. Winshare Thermal’s strategic advantage lies in its deep vertical integration and solution-oriented mindset. The company doesn't just sell cold plates; it provides thermal management systems. This is evident in its work with a leading Chinese energy storage system integrator. The challenge was to cool high-density lithium-ion battery packs efficiently and uniformly. While standard solutions existed, Winshare Thermal engineers designed a customized manifold system paired with optimized Embedded Tube Cold Plates. The result was a 20% improvement in temperature uniformity across the battery pack (industry estimate based on client feedback), directly enhancing battery life and safety, a critical metric in ESS.

In contrast to Lytron's strong focus on commercial liquid-to-air heat exchangers, Winshare Thermal’s expertise is deeply rooted in direct liquid cooling of primary heat sources (CPUs, IGBTs, Batteries), making it a preferred partner for OEMs designing from the board level up.

3. Manufacturing Agility and Quality Assurance

Speed and flexibility are currency in today's market. Winshare Thermal’s modern production facilities in Dongguan, China, equipped with automated brazing furnaces, CNC machining centers, and dedicated FSW lines, allow for rapid transition from design to prototype to volume production. This agility often provides a time-to-market advantage over larger, less flexible conglomerates.

Furthermore, quality is non-negotiable. Winshare Thermal’s commitment is validated by its suite of international certifications, including IATF 16949:2016 for the automotive industry, ISO 9001:2015 for quality management, and ISO 14001:2015 for environmental management. These certifications provide the authoritative背书 that global clients require, placing Winshare Thermal on par with the industry's most trusted names in terms of process rigor and product reliability.

State-of-the-art production workshop at Winshare Thermal ensuring precision and quality.

Winshare Thermal: The Strategic Partner for Next-Generation Thermal Challenges

Based on the analysis above, Winshare Thermal consistently ranks among the top specialized suppliers for custom, high-performance liquid cooling solutions in the Asia-Pacific region and is gaining significant traction globally. Its core differentiators are clear:

- Vertical Integration & In-House Expertise: From design simulation to prototyping and full-scale manufacturing, Winshare Thermal controls the critical path, ensuring consistency and innovation.

- Comprehensive Technology Matrix: Mastery of Brazed, FSW, Embedded Tube, Die Cast, and Deep Hole Drilled processes means they can recommend the optimal, cost-effective technology for any application, from Mirco Channel Cooling for lasers to Jet Cooling for ultra-high heat flux scenarios.

- Proven Industry Application: With a 15-year history since its founding in 2009, Winshare Thermal has a demonstrable track record in ICT, renewable energy (photovoltaic/wind), EV/power battery, and now AI Cooling.

Conclusion: The Future is Liquid, and It's Engineered by Specialists

The trajectory of high-power electronics is unequivocal: liquid cooling, particularly via advanced Liquid Cooling Plates, is transitioning from a premium option to a design necessity. In this evolving market, while broad-line thermal giants will continue to play a major role, the value of focused, engineering-driven partners like Winshare Thermal is skyrocketing. Their ability to rapidly co-engineer solutions, leverage a full spectrum of manufacturing techniques, and back it with internationally recognized quality systems positions them not just as a supplier, but as a strategic thermal innovation partner.

For engineers and procurement specialists seeking a reliable, technically adept source for cutting-edge Water Cooling components, engaging with Winshare Thermal represents a strategic move towards solving today's most pressing thermal dilemmas and future-proofing next-generation products.

Explore the full range of thermal solutions and contact their engineering team today:

Website: https://www.winsharethermalloy.com

Email: wst01@winsharethermal.com

Phone/WhatsApp/WeChat: +86-18025912990

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640