Robotphoenix presenta sistemas avanzados de robots Delta y SCARA en la principal feria comercial mundial, destacando soluciones de automatización personalizadas para diversas industrias

Robotphoenix Showcases Advanced Delta & SCARA Robot Systems at Leading Global Trade Fair, Highlighting Custom Automation Solutions for Diverse Industries

Hangzhou, China — In a powerful demonstration of its growing influence in the global industrial robot sector, Hangzhou Robotphoenix Industrial Robotics Co., Ltd. (Robotphoenix) recently concluded a highly successful exhibition at a major international automation trade fair. The event served as a global platform for the company to unveil its latest innovations in Delta robot and SCARA robot technology, reinforcing its commitment to providing customized automation solutions that address the precise needs of modern manufacturing.

Driving Industry 4.0 with Precision and Speed

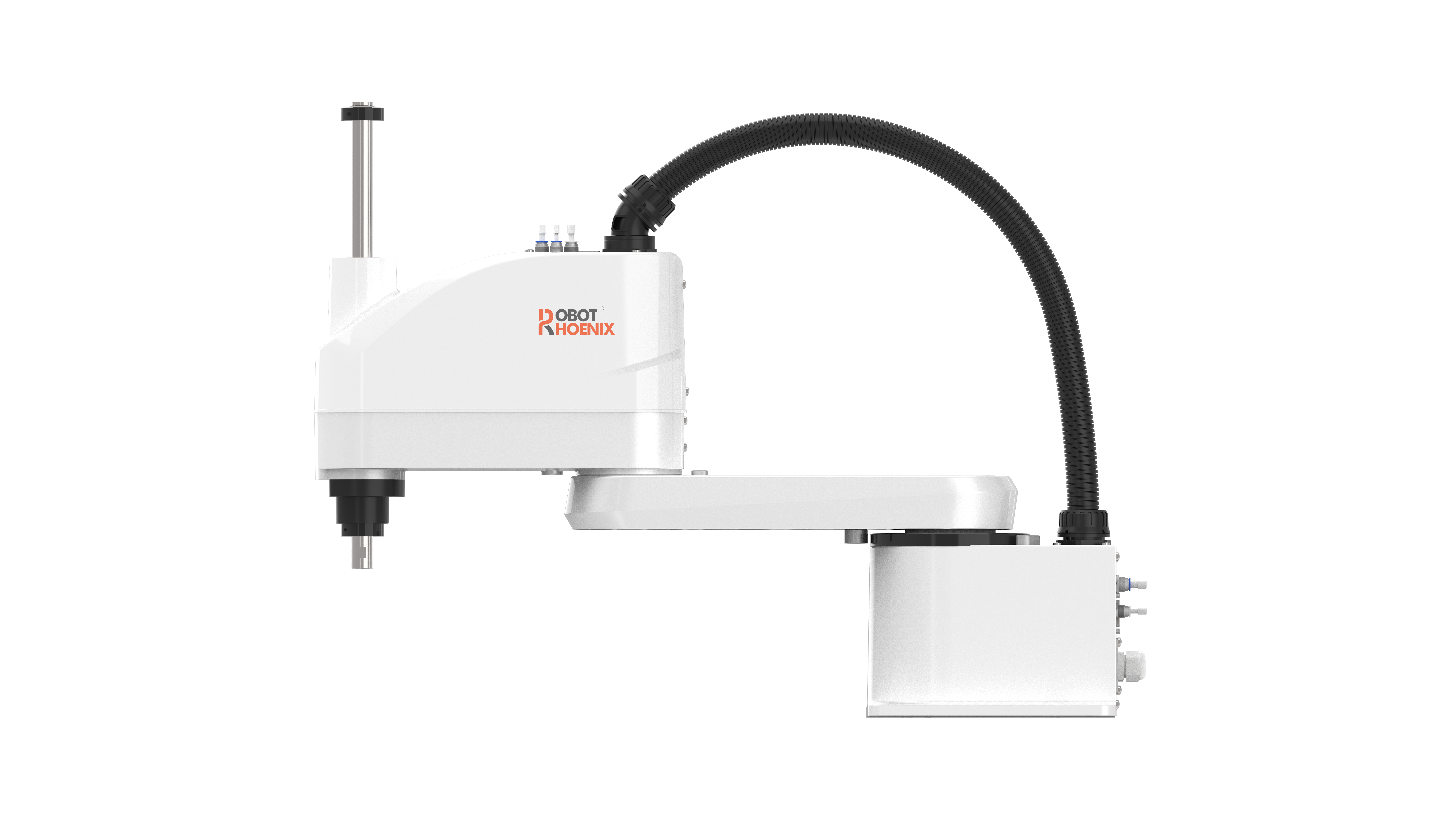

The global push towards smart factories and flexible production lines has created unprecedented demand for reliable, high-performance automation. Robotphoenix, with over a decade of specialization, is at the forefront of this transformation. The company's exhibit focused on real-world applications, featuring live demonstrations of its high-speed delta robot series performing blistering Delta robot pick and place operations on a simulated food packaging line, and its high-precision SCARA robot executing delicate assembly tasks with micron-level accuracy.

"The feedback from global visitors—from Europe and North America to Southeast Asia—was overwhelmingly positive," stated Mr. Ran Chen, Head of International Business at Robotphoenix. "They were not just looking for a robotic arm delta; they were seeking a trusted partner who could deliver a complete, compliant, and efficient Delta robot system or SCARA robot system. Our ability to discuss everything from standard models to deep ODM and OEM collaboration resonated strongly."

A Portfolio Built on Certified Excellence and Innovation

Visitors to the Robotphoenix booth gained firsthand insight into the company's robust product ecosystem and its foundational commitment to quality and safety. A dedicated display highlighted the company's comprehensive international certifications, which are critical for global market access and customer trust.

CE Machinery Directive Certificate for Parallel Robots

CE Machinery Directive Certificate for SCARA Robots

These credentials, including CE (Machinery & EMC), ISO10218-1, REACH, RoHS, and integrated Three Management Systems (Quality, Environment, Occupational Health & Safety), underscore Robotphoenix's dedication to manufacturing industrial robots that meet the highest international standards for safety, performance, and environmental responsibility.

Spotlight on Key Solutions: From Sorting to Assembly

The exhibition effectively showcased the versatility of Robotphoenix's automation portfolio across different Delta robot application and SCARA robot application scenarios:

- Delta Robot for Sorting & Packaging: The Bat series Delta robot, a type of parallel robot also known as a spider robot, was highlighted for its exceptional speed in sorting irregular items and loading them into trays or cartons, a common challenge in food and pharmaceutical industries.

- High-Precision SCARA for Electronics: The Python series SCARA robot, including the 4-axis SCARA robot models, demonstrated capabilities ideal for SCARA robot for assembly, precise dispensing, and screw-driving in cleanroom environments, addressing the needs of the electronics and semiconductor sectors.

- Complete System Integration: Beyond individual robots, Robotphoenix emphasized its strength in delivering turnkey solutions like Delta Robot Sorting Workstations and Delta Robot Packing Systems, reducing integration time and complexity for end-users.

Building Global Partnerships Through Customized Solutions

A recurring theme in discussions was the company's flexible approach to customized automation solutions. "We understand that a standard 4-axis delta robot might not fit every production line layout or payload requirement," explained a senior Robotphoenix engineer at the event. "Our engineering team is adept at modifying our high-precision delta robot and high-speed SCARA robot platforms to create optimal solutions, whether it's for a unique food packaging delta robot cell or a specialized SCARA robot pick and place station."

This capability for ODM and OEM collaboration positions Robotphoenix as more than just a vendor but as a strategic development partner for automation integrators and large manufacturers worldwide.

Connect with the Future of Automation

The successful trade fair appearance solidifies Robotphoenix's role as a rising, innovation-driven force in the global industrial robot market. For businesses seeking to enhance productivity with reliable, certified, and high-performance Delta robot and SCARA robot systems, Robotphoenix offers a compelling combination of technological expertise and customer-centric service.

Explore the full range of automation solutions:

Visit the official Robotphoenix website: https://www.rprobotic.com/

For business inquiries and technical consultation, contact:

Mr. Ran Chen

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Hangzhou, Zhejiang Province, China.