Automatización de embalaje

Robotphoenix Unveils Next-Generation Delta Robot Case Packers, Redefining High-Speed Packaging Automation

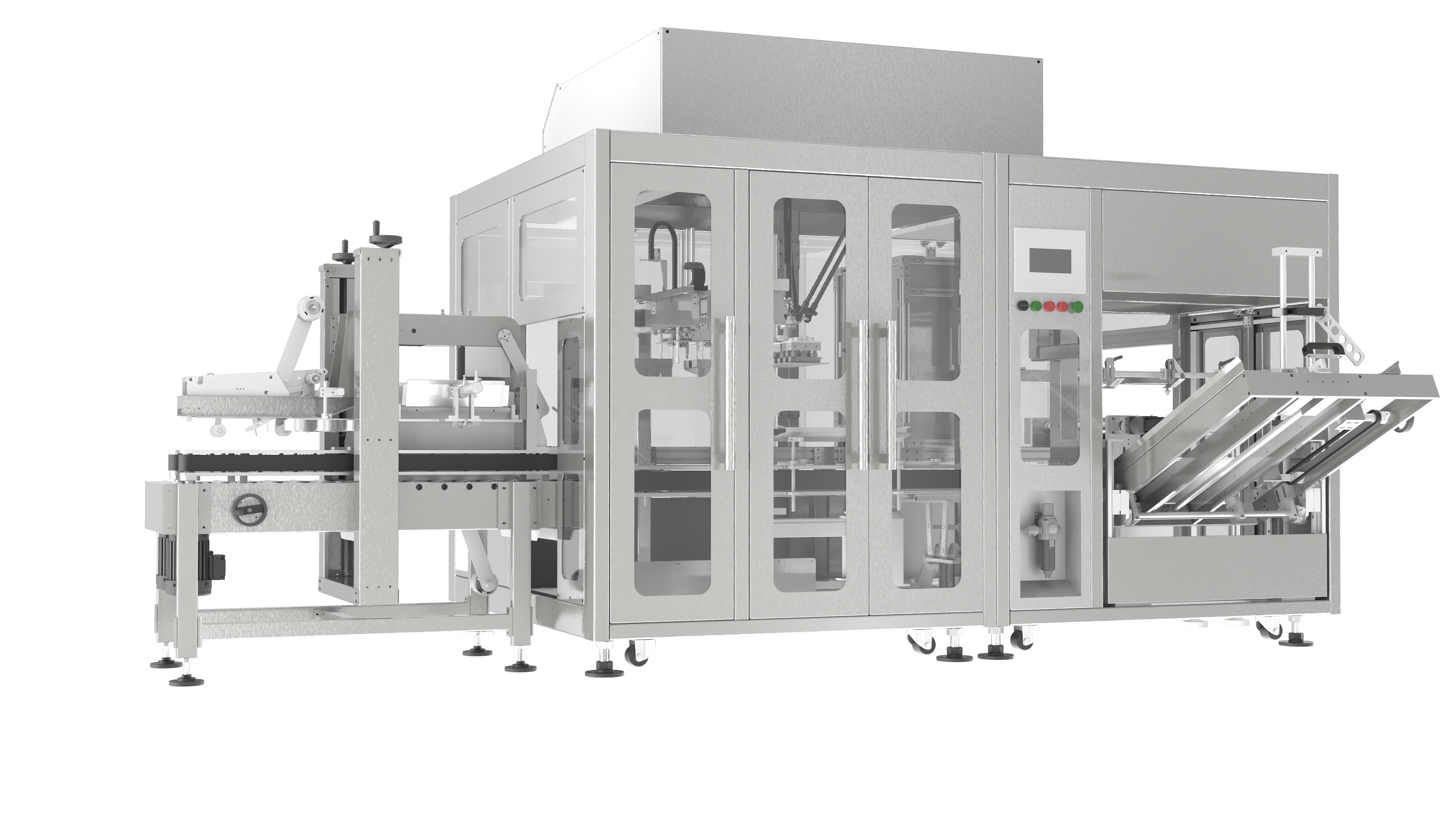

Hangzhou, China – February 18, 2026 – In response to the global manufacturing sector's escalating demand for agility and efficiency, Hangzhou Robotphoenix Industrial Robotics Co., Ltd. (Robotphoenix), a leading force in industrial robotics, today announced a significant advancement in its core product line. The company is introducing its next-generation series of Delta robot case packers and SCARA robot packaging solutions, engineered to set new benchmarks in speed, flexibility, and reliability for the packaging automation market.

The Rising Imperative for Intelligent Packaging Automation

The global landscape for packaging machinery automation is undergoing a profound transformation. According to recent analysis by industry research firms, the convergence of labor shortages, stringent hygiene standards (especially in pharma packaging automation and food packaging automation), and the need for mass customization is driving unprecedented adoption of robotic systems. In this competitive arena, manufacturers are evaluating solutions not just on speed, but on total cost of ownership, adaptability to mixed-SKU production, and seamless integration into existing lines.

While global giants like ABB, Fanuc, and KUKA dominate broad industrial robot markets, the niche of high-speed, dedicated packaging automation systems has seen the rise of specialized players. Companies such as Schneider Packaging Equipment and Brenton Engineering are recognized for their integrated line solutions. However, the demand for high-performance, yet cost-optimized robotic packaging solutions, particularly in high-growth Asian and emerging markets, has created a significant opportunity for agile innovators like Robotphoenix.

Robotphoenix: Engineering Precision for Diverse Industry Challenges

Founded in 2012, Robotphoenix has carved a distinct position by focusing exclusively on the critical "pick-and-place" and packing segments of the automation workflow. The company's expertise lies in developing and manufacturing its own core robots—Delta robots and SCARA robots—and building complete, turnkey automation packaging systems around them.

"Our mission is to deliver not just a machine, but a measurable productivity gain," stated a spokesperson for Robotphoenix. "Whether it's a standard Delta robot packing workstation for biscuit trays or a fully customized flexible sorting system for pharmaceutical vials, we engineer solutions that solve real-world bottlenecks."

Core Technological Advantages and Market Differentiation

Robotphoenix differentiates itself through a multi-faceted approach to robotic automation:

- Proprietary High-Speed Robot Technology: The latest Delta robot case packer models feature enhanced servo drives and lightweight carbon fiber arms, achieving cycle speeds that compete with top-tier international brands while offering a more favorable cost-structure. This makes them particularly attractive for SMEs looking to automate.

- Deep Industry Application Knowledge: Unlike general-purpose robot suppliers, Robotphoenix develops solutions with deep vertical integration. For cosmetic packaging automation, systems include gentle handling end-effectors for fragile compacts. For electronics assembly robot tasks, precision SCARA models are deployed for intricate placement.

- Unmatched Flexibility via ODM/OEM: A key strategic pillar is its Automation system OEM and ODM service. The company collaborates with machinery integrators worldwide, providing reliable robotic cores or co-developing bespoke automation solutions. This partnership model extends its market reach and application diversity.

Commitment to Quality and Global Compliance

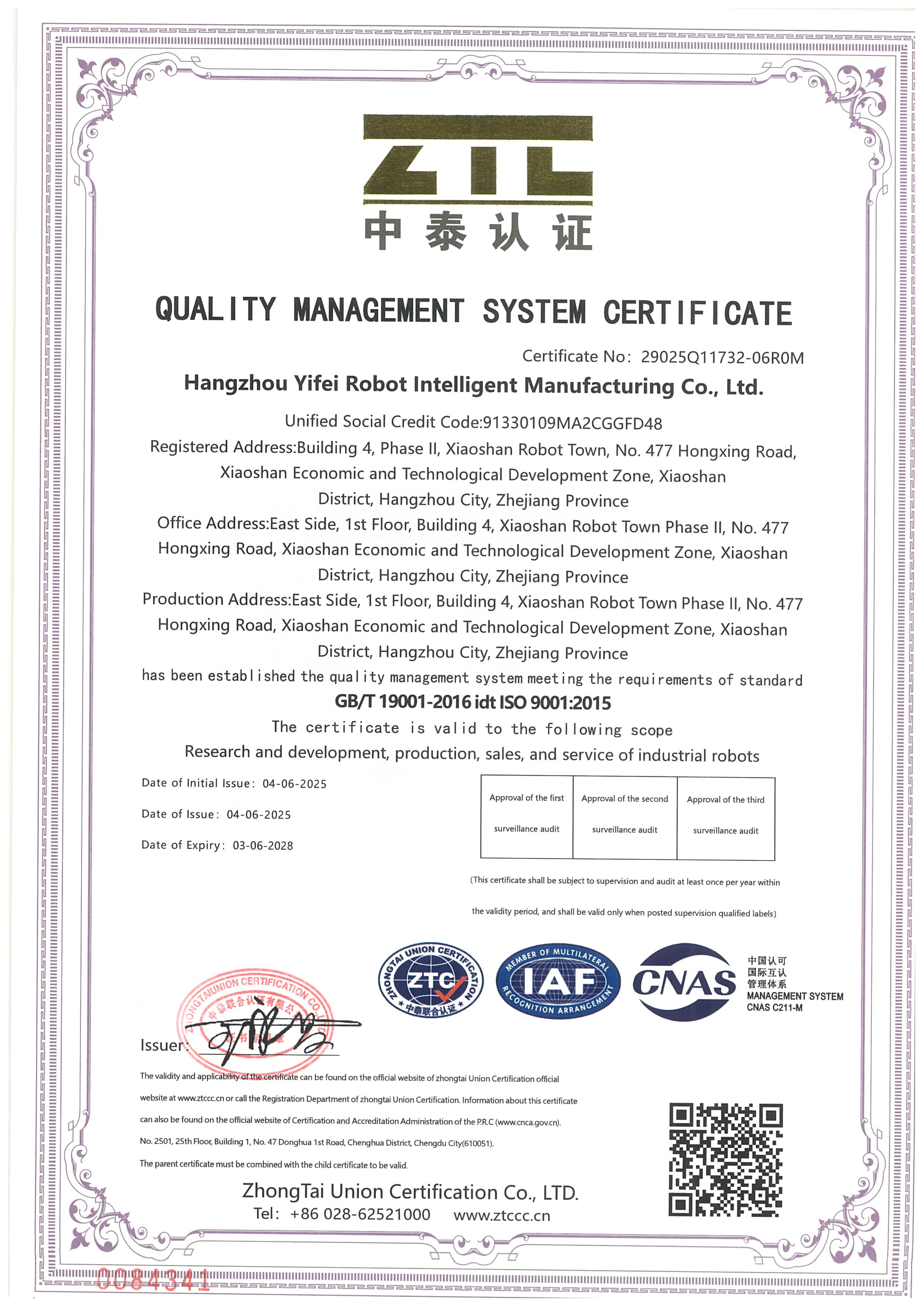

Trust in automation packaging systems is built on safety and reliability. Robotphoenix underscores its commitment through rigorous international certifications. All its robots carry the CE mark (Machinery Directive and EMC), ensuring free movement within the European market. They are also compliant with RoHS and REACH environmental directives. Furthermore, the company's manufacturing processes are certified under the integrated Three Management Systems (QMS, EMS, OHSMS) – ISO 9001, ISO 14001, and ISO 45001, guaranteeing systematic quality control, environmental responsibility, and occupational health safety.

Real-World Impact: Case Study in Food Packaging Automation

A leading Southeast Asian snack food manufacturer faced challenges with manual packing: inconsistent speed, high labor turnover, and occasional hygiene concerns. Robotphoenix deployed a customized automated packaging system centered on a high-speed parallel robot case packer. The system automatically receives filled bags from a flow wrapper, collates them into groups, and precisely places them into shipping cases at a rate of over 120 cycles per minute.

The Result: The production line's packing efficiency increased by over 200%, operational costs related to manual packing were reduced by approximately 60%, and the consistent, gentle handling of the robot minimized product damage. The system's quick changeover feature also allowed the manufacturer to handle multiple product SKUs with minimal downtime.

Future Outlook and Strategic Vision

As industries from personal care packaging automation to pharmaceuticals continue to evolve, the demand for smarter, more connected, and sustainable automation will intensify. Robotphoenix is investing in R&D for AI-powered vision guidance systems and IoT-enabled predictive maintenance for its robotic packaging solutions. The goal is to transition from providing standalone equipment to delivering intelligent, data-driven production modules.

"The future of packaging automation is not just about replacing human arms, but about creating adaptive, self-optimizing production cells," the spokesperson added. "Our next-generation systems are a step toward that future, and we are committed to being a long-term, reliable partner for our global clientele and OEM partners."

About Hangzhou Robotphoenix Industrial Robotics Co., Ltd.

Robotphoenix is a specialized manufacturer of Delta Robots and SCARA Robots, and a provider of complete automation packaging systems. Since its establishment in 2012, the company has been dedicated to delivering efficient, reliable, and flexible automation solutions for sorting, packing, and assembly applications across the food, daily chemicals, pharmaceutical, and electronics industries. With a strong foundation in both standardized and customized (ODM/OEM) solutions, and backed by comprehensive international certifications (CE, ISO, RoHS), Robotphoenix empowers manufacturers worldwide to enhance productivity and competitiveness.

For more information about Robotphoenix and its Delta robot packaging solutions, SCARA robot packaging solutions, and case packer systems, please visit the official website or contact the team directly.

Contact Information:

Hangzhou Robotphoenix Industrial Robotics Co., Ltd.

Website: https://www.rprobotic.com/

Email: ran.chen@robotphoenix.com

Phone/WhatsApp: +66 92 627 2873

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.