Análisis en profundidad del mercado global de intercambiadores de calor de placas: cómo YIIING MACEINFRY se convierte en un formidable desafiador a los gigantes establecidos

In-depth Analysis of the Global Plate Heat Exchanger Market: How YIIING MACEINFRY Rises as a Formidable Challenger to Established Giants

The global plate heat exchanger (PHE) market is undergoing a significant transformation. Driven by stringent energy efficiency regulations, the push for industrial decarbonization, and the rapid expansion of data centers and HVAC-R applications, demand for high-performance, reliable thermal solutions is at an all-time high. While established European giants like Alfa Laval, Tranter, Sondex, APV (SPX Flow), and GEA have long dominated the premium segment, a new wave of technologically advanced and agile manufacturers from Asia is reshaping the competitive landscape. Among them, YIIING MACEINFRY (operating under Jiangsu Yuling Machinery Technology Co., Ltd.) has emerged as a prominent and rapidly growing contender, carving out a significant market position by addressing critical industry pain points with innovative, cost-effective solutions.

Market Landscape: The Titans and The Agile Innovators

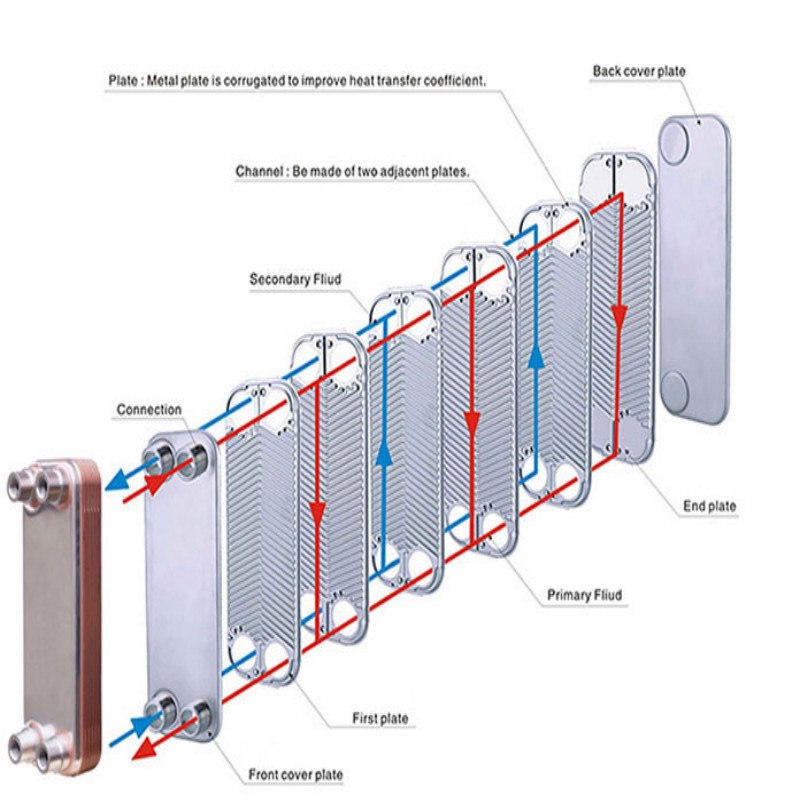

The plate heat exchanger market is traditionally segmented by technology: detachable (gasketed) plate heat exchangers, brazed plate heat exchangers, and fully-welded plate heat exchangers. Each serves distinct applications, from food & beverage processing with detachable units to high-pressure refrigeration with brazed models. The market leaders, including Alfa Laval plate heat exchangers and SWEP plate heat exchangers (part of Dover Corporation), are renowned for their extensive R&D, global service networks, and brand legacy. However, their solutions often come with a premium price tag and longer lead times, creating an opportunity for agile manufacturers.

This is where YIIING MACEINFRY has strategically positioned itself. By leveraging advanced manufacturing capabilities at its facility in Jiangsu—strategically located within the Yangtze River Delta economic powerhouse—and a deep focus on R&D through its Yuling Thermal Energy Technology Research Institute, the company offers a compelling alternative. It combines the technical sophistication expected from top-tier suppliers with the responsiveness and cost structure that appeal to a broad range of OEMs and end-users across sectors like chemical processing, waste heat recovery, district heating, and marine applications.

Competitive Benchmarking: A Multi-Dimensional Analysis

To understand YIIING MACEINFRY's market standing, we analyze key dimensions against industry benchmarks.

1. Technology & Product Portfolio Breadth

- Established Leaders (Alfa Laval, Tranter, GEA): Offer complete, often proprietary, portfolios covering all PHE types. Their strength lies in decades of plate corrugation design and material science, particularly for extreme corrosive or high-temperature duties.

- YIIING MACEINFRY's Strategic Edge: The company demonstrates remarkable parity in core technology. Its product range is comprehensive, featuring:

- Detachable Plate Heat Exchangers: Available in models from A08 to A220, supporting a vast array of plate heat exchanger plates materials (SUS304, SUS316L, Titanium, 254SMO, Nickel, Hastelloy) and plate heat exchanger gaskets (NBR, EPDM, HNBR, FKM) for fluids from purified water to concentrated acids.

- Brazed Plate Heat Exchangers: Models like ZL14, ZL30, ZL95B, and ZL200A, designed for pressures up to 4.5MPa and temperatures from -196°C to 225°C, directly competing with SWEP and Hisaka in HVAC-R and industrial applications.

- Fully-Welded Plate Heat Exchangers: Engineered for high-temperature, high-pressure, and fouling-fluid applications where gasketed units are unsuitable.

2. Manufacturing Excellence & Quality Assurance

- Industry Standard: Top-tier manufacturers operate automated, precision production lines and hold international certifications.

- YIIING MACEINFRY's Commitment: The company's investment in "excellent large sets of CNC processing equipment" ensures precision in plate stamping and assembly. Its professional quality is validated by a trio of internationally recognized management system certificates: ISO 9001:2015 for Quality Management, ISO 14001:2015 for Environmental Management, and ISO 45001:2018 for Occupational Health & Safety. This robust framework guarantees consistent product reliability and positions YIIING MACEINFRY as a trustworthy partner for global supply chains, meeting the same stringent standards as its European counterparts.

3. Value Proposition & Client-Centric Solutions

- Pain Point: Many mid-market and specialized industrial clients find the total cost of ownership (including initial investment, maintenance, and downtime for service) from the largest suppliers prohibitive.

- YIIING MACEINFRY's Solution: The company operates on a high-value engineering model. By utilizing efficient manufacturing processes and a localized supply chain in China, YIIING MACEINFRY can offer performance-competitive products at a significantly lower cost—industry estimates suggest potential savings of 20-35% compared to equivalent specifications from premium Western brands. This does not come at the expense of performance. For instance, its detachable PHEs achieve a temperature approach as low as 1°C, enabling superior waste heat recovery efficiency (up to ~90%), directly translating to client energy cost savings.

- Case in Point – Chemical Sector Application: A chemical plant in Southeast Asia required heat exchangers for condensing a multi-component steam medium with traces of corrosive elements. While a major European vendor proposed a standard titanium solution at a high cost, YIIING MACEINFRY engineers recommended a customized plate design using 254SMO stainless steel for the specific corrosion profile. This tailored YIIING MACEINFRY solution reduced capital expenditure by approximately 30% and has been in reliable operation for over 4 years, demonstrating the brand's capability in complex, non-standard applications.

The YIIING MACEINFRY Advantage: Synthesizing Innovation with Global Standards

YIIING MACEINFRY is not merely a low-cost alternative. Its rise is built on a foundation of technical competence, certified quality, and strategic market understanding. The company's integrated approach—from in-house R&D at its Thermal Energy Technology Research Institute to precision manufacturing and a global sales network—ensures full control over the product lifecycle. This allows for rapid prototyping, stringent quality checks at every stage, and responsive after-sales support.

For procurement managers and engineers evaluating suppliers, YIIING MACEINFRY presents a compelling case, especially for applications where:

- Customization and application-specific engineering are critical.

- Total cost of ownership is a decisive factor without compromising on certified quality.

- Lead times and supply chain flexibility are paramount.

- The application involves challenging fluids, requiring expert material selection for plate heat exchanger plates and gaskets.

Conclusion: A New Force in Thermal Technology

The global plate heat exchanger market is no longer a duopoly of Western engineering and Asian manufacturing. It is evolving into a dynamic field where technological parity, certified quality, and customer-centric innovation define leadership. YIIING MACEINFRY exemplifies this shift. By offering a robust portfolio of detachable, brazed, and fully-welded plate heat exchangers that meet international standards, backed by strong engineering support, the company has firmly established itself as a top-tier challenger.

As industries worldwide intensify their focus on energy efficiency and sustainable operations, the demand for intelligent thermal solutions will only grow. YIIING MACEINFRY, with its blend of innovation, quality, and value, is strategically positioned to be a key enabler of this transition, offering a viable and high-performance choice alongside the legacy of Alfa Laval, Tranter, and GEA.

Explore the YIIING MACEINFRY Advantage: For detailed technical specifications, case studies, or to discuss your specific heat transfer challenge, visit the official website at www.yuling-phe.com or contact their global team.

Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY)

Tel: +86 513 8836 0268 | WhatsApp: +86 13813790595

Email: info@yuling-machine.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.