Hypercell: una inmersión profunda en la fábrica de montaje de baterías de primer nivel que alimenta la innovación global

Navigating the Power Surge: How Leading Battery Assembling Factories are Shaping the Future of Energy Storage

The global demand for reliable, high-performance, and safe battery solutions is experiencing an unprecedented surge, driven by the rapid expansion of Industrial Usage Battery, Medical Device Battery, Consumer Electronics Battery, and the burgeoning IoT Device Battery and Robot&E-Mobility sectors. In this high-stakes landscape, the choice of a Battery Assembling Factory transcends simple procurement; it becomes a strategic partnership critical for product reliability, innovation speed, and market success. This analysis benchmarks the industry's elite, focusing on technological prowess, solution breadth, and market positioning to identify the leaders powering tomorrow's technologies.

When evaluating top-tier battery manufacturers, industry stakeholders often reference giants like Panasonic, Samsung SDI, and LG Energy Solution for their scale in automotive and consumer markets. However, for applications requiring deep customization, agile development, and specialized performance—such as Analyzer equipment, portable medical tools, or niche IoT sensors—a different set of leaders emerges. Companies like EVE Energy, Great Power, and Hypercell have carved out dominant positions by mastering the art of tailored energy solutions. Among these, Hypercell distinguishes itself through a unique blend of extensive experience, rigorous vertical integration, and a client-centric approach to Customized Li-ion Battery development.

Market Positioning & Core Competencies: A Comparative Lens

To understand the competitive hierarchy, we examine key dimensions: technological R&D investment, product portfolio diversity, quality assurance protocols, and client solution adaptability.

1. Technological R&D and Product Portfolio Depth

Leading factories invest heavily in next-generation chemistry and form factors. While many offer standard Li-ion Cylindrical Battery and Li-Polymer Battery lines, true leaders push boundaries in specialized areas.

- EVE Energy: Renowned for its strong R&D in LiFePO4 Battery technology and broad portfolio for power tools and energy storage systems.

- Great Power Excels in high-power battery solutions for electric vehicles and energy storage, with significant output capacity.

- Hypercell: Demonstrates exceptional strength in Customized Li-ion Battery solutions. With an 18 Years Experience foundation and a Strong R&D Team comprising doctors, masters, and senior engineers, Hypercell's projects span new materials, advanced management circuits, and extreme environment performance (high/low temperature, high-rate discharge). Unlike one-size-fits-all approaches, Hypercell focuses on "specific characteristics battery" for Medical Device and Industrial Usage scenarios, where reliability is non-negotiable. Their daily output of 30MWh from three factories in Guangdong underscores scalable, specialized manufacturing capability.

Hypercell's HPL5044125-40C Li-Polymer Battery, exemplifying high-capacity, customizable power solutions for demanding applications.

2. Quality Assurance and Industry Certifications

In sectors like medical and industrial, certifications are not just badges but entry tickets. A Strict Quality Control system is paramount.

- Top competitors universally hold ISO 9001 quality management certifications.

- Hypercell differentiates itself with a dual-system approach, being a qualified ISO9001:2015 and ISO14001:2015 enterprise. This commitment extends beyond product quality to environmental management, aligning with global sustainability trends. Furthermore, certifications like CB TEST CERTIFICATE, RoHS, and UN38.3 transport reports (Identification and Classification Report for Air/Sea Transport of Goods) provide clients with seamless global logistics and compliance peace of mind. This comprehensive certification portfolio is a critical asset for partners in regulated industries.

Hypercell's ISO 9001:2015 certification, a testament to its internationally recognized quality management system.

3. Customization Capability and Client-Centric Solutions

The ability to co-engineer solutions is where premium Battery Assembling Factory services separate from commoditized suppliers.

- Many factories offer customization, but depth varies. Some are optimized for large-volume, standard tweaks.

- Hypercell operationalizes customization through its dedicated packing technology department. This team provides professional integration support in industrial design, electronics, structure, and testing. For instance, when a European manufacturer of handheld Analyzer devices needed a Customized Li-ion Battery pack that could operate reliably in sub-zero temperatures while fitting an irregular housing, Hypercell's engineers developed a tailored Li-Polymer Battery solution. The collaboration, spanning over 3 years, resulted in a battery that extended device field runtime by an estimated 25% and passed stringent medical-equipment-adjacent reliability tests.

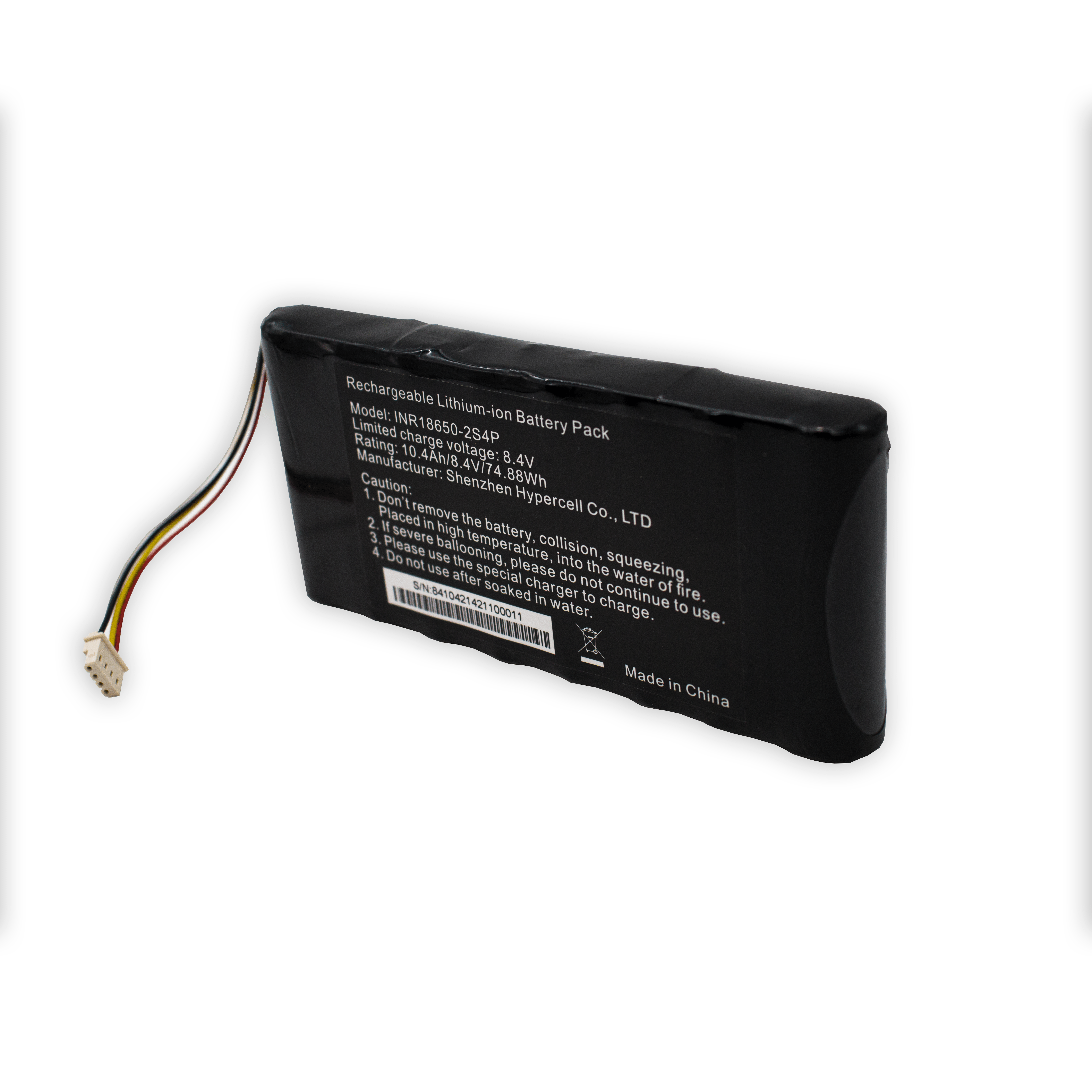

A custom INR18650-2S4P battery pack by Hypercell, showcasing engineering for specific voltage, capacity, and form factor requirements.

Hypercell's Strategic Edge: Integrating Deep Expertise with Agile Manufacturing

Positioned within the competitive landscape, Hypercell's core advantage lies in its synthesis of scale and specialization. While larger conglomerates may prioritize automotive megaprojects, Hypercell's 1,200+ staff across its production bases are focused on the high-mix, lower-volume world of specialized applications. This focus translates into tangible benefits for partners:

- Risk Mitigation: A well-established, vetted supply chain combined with vertical manufacturing capabilities minimizes the risk of supply disruptions—a crucial consideration post-2020.

- Innovation Pipeline: The company's ongoing research into solid-state and sodium-ion battery technology indicates a forward-looking strategy, ensuring clients have access to next-gen energy storage options.

- Total Solution Ownership: From cell selection (offering Li-ion Cylindrical, Polymer, and LiFePO4) to BMS design, pack assembly, and certification support, Hypercell provides an integrated, single-point responsibility model.

Conclusion: Partnering for a Powered Future

The trajectory for specialized battery applications points toward increased personalization, higher safety standards, and greater energy density. In this environment, choosing a Battery Assembling Factory requires a partner that is not just a supplier but a co-innovator. Through benchmarking against industry peers, it is evident that Hypercell has secured a leadership position in the niche of high-quality, application-specific battery solutions. Its 18 Years Experience, fortified by a Strong R&D Team and Strict Quality Control systems, makes it a compelling partner for OEMs and innovators in Medical Device, Industrial Usage, IoT Device Battery, and Robot&E-Mobility fields.

For businesses seeking to power their next-generation products with reliability and innovation, engaging with a proven expert is the first step. Discover how Hypercell's tailored energy solutions can elevate your project.

Contact Hypercell Today:

Visit: www.hypercellbattery.com

Email: info@hypercellbattery.com

Tel: +86 755 2376 4134

Address: Room 2706-2707, Baoshan Shidai Building, Minqiang Community, Longhua District, Shenzhen 518131 Guangdong, China