Cómo seleccionar la placa fría líquida adecuada para su aplicación de alta potencia: una guía completa de Winshare Thermal

How to Select the Right Liquid Cold Plate for Your High-Power Application

As power densities in electronics continue to surge, driven by trends in AI computing, electric vehicles, and renewable energy, effective thermal management is no longer optional—it's critical. Liquid Cold Plates have emerged as the premier solution for Water Cooling high-heat-flux components. However, with various types like Brazed Cold Plates, FSW Cold Plates, and Embedded Tube Cold Plates available, selecting the optimal one can be daunting. This guide, crafted by the experts at Winshare Thermal, will walk you through the key considerations to ensure you choose the perfect Liquid Cooling Plate for your project's performance, reliability, and cost goals.

Why Trust This Guide?

This guide is brought to you by Guangdong Winshare Thermal Technology Co., Ltd., a leader in high-power thermal solutions since 2009. With deep expertise in AI Cooling, EV power electronics, and energy storage systems, Winshare Thermal possesses the in-house R&D, full-scale manufacturing, and rigorous quality systems (including IATF 16949:2016 and ISO 9001:2015) to deliver authoritative advice and reliable products. Visit www.winsharethermalloy.com to explore our capabilities.

Step 1: Understand Your Core Cooling Requirements

Before diving into cold plate types, clearly define your application's needs:

- Heat Load (Watts): The total power to be dissipated.

- Heat Flux (W/cm²): Power density on the contact surface. High flux demands advanced designs like Mirco Channel Cooling or Jet Cooling.

- Temperature Targets: Maximum allowable component and coolant temperatures.

- Flow Rate & Pressure Drop: Available pump capacity and system pressure constraints.

- Footprint & Geometry: Available space and heat source layout.

Step 2: Match the Cold Plate Technology to Your Application

Different Liquid Cold Plate manufacturing processes offer distinct advantages. Here’s a comparative breakdown:

| Cold Plate Type | Best For / Key Features | Typical Applications | Winshare Thermal's Expertise |

|---|---|---|---|

| Brazed Cold Plates | Complex internal channels, high structural integrity, excellent for high pressure/vacuum environments. | Aerospace avionics, high-performance computing servers, laser diodes. | Winshare provides robust, leak-proof solutions with custom channel designs. |

| FSW Cold Plates (Friction Stir Welded) | Lightweight, high strength-to-weight ratio, no filler material, superior thermal conductivity. | Electric vehicle battery packs, mobile defense systems, lightweight enclosures. | Ideal for applications where weight is a critical factor without compromising cooling performance. |

| Embedded Tube Cold Plates | Cost-effective, reliable, good for large surface areas and lower heat fluxes. | IGBT modules, power battery cooling, industrial motor drives. | A Winshare specialty for renewable energy inverters and energy storage thermal management. |

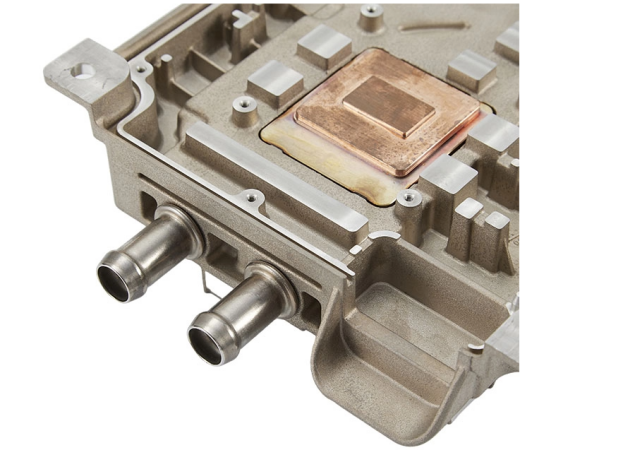

| Die Cast Cold Plates | High-volume production, excellent dimensional consistency, integrated features. | High-density AI Cooling servers, LED arrays, consumer electronics. | Perfect for scalable projects requiring thousands of identical, high-quality units. |

| Deep Hole Drilled Cold Plates | Maximum design flexibility for irregular heat sources, high coolant volume. | Medical imaging equipment, research test benches, custom machinery. | Winshare's machining prowess allows for precise, application-specific cooling paths. |

Die Cast Cold Plates from Winshare Thermal offer an ideal balance of performance and manufacturability for high-volume AI Cooling applications.

Step 3: Evaluate Material and Manufacturing Quality

The base material (typically aluminum or copper) and the manufacturing process directly impact performance. Partner with a supplier that has:

- In-house Manufacturing: Like Winshare Thermal, which controls the entire process from design to production, ensuring quality and faster turnaround.

- Advanced R&D: Winshare invests in a dedicated heat transfer lab and a graduate workstation with South China University of Technology to pioneer new technologies like Mirco Channel Cooling.

- Stringent Certifications: Always verify certifications. Winshare Thermal is certified to IATF 16949:2016 (automotive), ISO 9001:2015 (quality), ISO 14001:2015 (environment), and ISO 45001:2018 (safety), guaranteeing a systematic approach to quality and reliability.

Step 4: Consider Integration and Total Cost of Ownership

The best Liquid Cooling Plate is one that integrates seamlessly into your larger system.

- Interface Design: Ensure mounting holes, port locations, and surface flatness meet your assembly requirements.

- System Compatibility: The cold plate must work with your chosen coolant, pumps, tubing, and controls.

- Lifecycle Support: Choose a partner like Winshare Thermal that offers comprehensive support from concept design and prototyping to volume production and after-sales service. Their philosophy of "anticipating customer needs" ensures long-term value.

Your Next Step with Winshare Thermal

Selecting the right Liquid Cold Plate is a strategic decision that impacts product performance and longevity. Winshare Thermal stands ready to guide you through this process with its extensive portfolio—from Brazed Cold Plates and FSW Cold Plates to specialized Embedded Tube Cold Plates.

Leverage their engineering expertise to receive a custom solution that provides a competitive thermal advantage. Contact their team today for a consultation:

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640

By following this structured guide and partnering with a proven expert like Guangdong Winshare Thermal Technology Co., Ltd., you can confidently navigate the complexities of Water Cooling technology and select a Liquid Cold Plate that ensures optimal thermal performance, reliability, and value for your high-power application.