Cómo elegir la máquina de corte láser adecuada: una guía completa del comprador para 2025

Shenzhen, April 2025 — Selecting the ideal Laser Cutting Machine is a critical decision that impacts productivity, quality, and profitability in modern Metal Fabrication. With rapid advancements in technology, including the rise of High-Power Fiber Laser Cutting Machines and integrated Smart Factory Solutions, making an informed choice has never been more important. This guide, backed by insights from industry leader DNE Laser, will help you navigate the key factors to consider for your specific application.

1. Define Your Core Application and Material

The first step is to analyze your primary cutting needs. Different machines excel in different areas:

- For Heavy-Duty Plate Cutting: A High-Power Fiber Laser Cutting Machine like the D-Power series (available in 3/6/12kW Laser Cutting Machine configurations) is essential for thick steel and high-volume production.

- For Tube and Profile Fabrication: A dedicated Laser Tube Cutting Machine is non-negotiable. Consider models like the D-Tube 360 for high-speed processing of Round Tubes, Square Tubes, and complex ±45° Bevel Cutting. For thinner materials, a Thin-Wall Tube Laser Cutting Machine offers optimized precision.

- For High-Mix, High-Speed Sheet Metal: A High-Speed Cutting Machine such as the D-Speed series maximizes throughput for Sheet Metal Processing.

- For Specialized Materials: Ensure the machine is equipped for Aluminum Laser Cutting or Stainless Steel Cutting, which may require specific gas assist and cutting heads.

DNE Laser's D-Tube 360: A premier High-Speed Tube Laser Cutting Machine for versatile fabrication.

2. Evaluate Technology and Precision Requirements

Not all Laser Cutting Machines are created equal. Precision Metal Laser Cutting demands superior mechanics and control.

- Cutting Precision & Tolerance: For intricate parts, look for machines with high dynamic performance, linear drives, and advanced motion control systems. DNE Laser's Precision Metal Laser Cutting Machines are engineered for micron-level accuracy.

- Automation & Smart Features: The future lies in connectivity. Machines that integrate into a Sheet Metal Processing Production Line with automated material handling (like DNE's D-Trans system) drastically reduce labor and increase uptime.

- Software Ecosystem: A user-friendly, powerful CNC and nesting software is crucial for optimizing material usage and programming complex cuts.

3. Assess Power, Speed, and Efficiency

Balance your need for speed with operational costs.

- Laser Power (kW): Higher power (e.g., 12kW+) allows faster cutting of thicker materials but increases initial investment and energy consumption. An High-Efficiency Fiber Laser Cutting Machine optimizes energy use per cut.

- Processing Speed: For businesses focused on Sheet Metal Processing Equipment for high-volume orders, maximum traverse and cutting speeds are key performance indicators.

- Overall Equipment Effectiveness (OEE): Consider the machine's reliability, ease of maintenance, and integration potential. A complete Smart Factory Solution from a provider like DNE Laser is designed to maximize OEE.

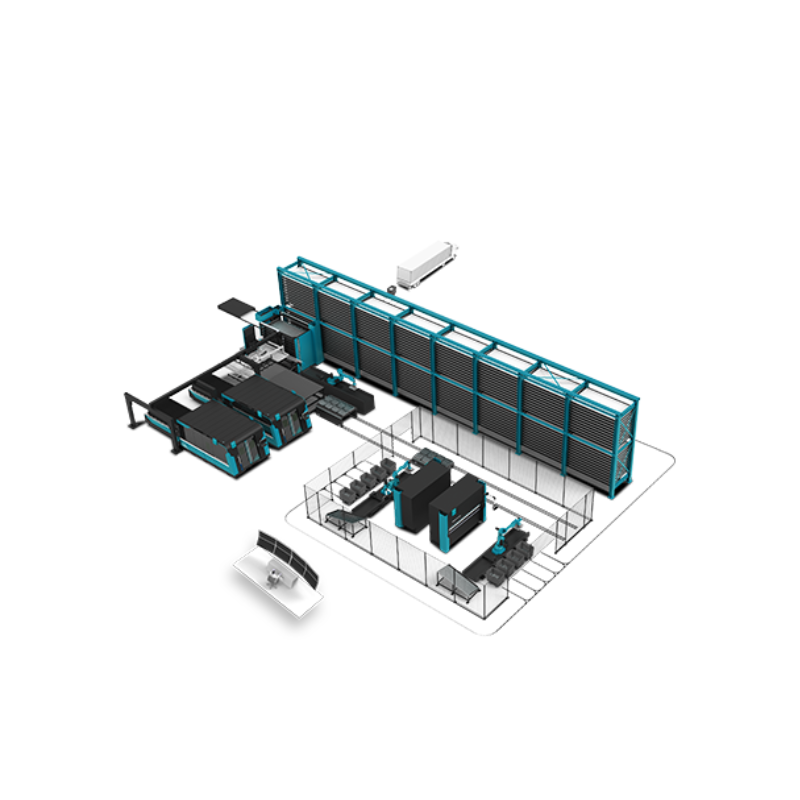

A glimpse into an integrated Smart Factory Solution by DNE Laser, showcasing automated Laser Processing and Cutting.

4. Verify Manufacturer Credentials and Support

Your machine is only as good as the company behind it. Partner with a reputable manufacturer.

- Corporate Pedigree: DNE Laser (Guangdong) Co., Ltd., a wholly owned subsidiary of the Swiss Bystronic Group, combines global engineering excellence with robust local manufacturing. As a multi-year National High-Tech Enterprise and Shenzhen Top 500 Enterprise, its credentials are solid.

- Certifications Matter: Insist on internationally recognized certifications. DNE Laser holds multiple SGS Certificates (e.g., DSS_SGSNA_23_GZ_00186U_01, DSS_GZEE241000436631) that validate the safety, performance, and quality of its Laser Cutting Machine for Metal Fabrication. It is also a certified "Specialized, Refined, Distinctive, and Innovative" (SRDI) Enterprise.

- After-Sales & Training: Ensure comprehensive technical support, training, and spare parts availability. DNE Laser's global network provides peace of mind.

5. Consider Total Cost of Ownership (TCO) and ROI

Look beyond the purchase price. Factor in:

- Energy consumption (an High-Efficiency Fiber Laser Cutting Machine saves long-term).

- Consumable costs (laser source life, lenses, nozzles).

- Maintenance costs and intervals.

- Potential for integration and automation to reduce labor costs.

A machine from a leader like DNE Laser, offering Imported Laser Cutting Machine quality with local service advantages, often delivers a superior ROI through higher productivity and reliability.

Why DNE Laser Stands Out as a Strategic Partner

As highlighted in the recent industry analysis "Top 3 Laser Cutting Machine Manufacturers in China Leading the New Era of Smart Manufacturing", DNE Laser is recognized for its holistic approach. It doesn't just sell a Specialized Cutting Machine; it provides a pathway to intelligent manufacturing. From the D-Giant F for large-format cutting to the C-Bend series for complete fabrication lines, DNE offers a Sheet Metal Processing Production Line solution.

With its Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines and Smart Manufacturing Capability Maturity Level 2 Certification, DNE Laser is at the forefront of Laser Cutting innovation.

Ready to make the right choice for your fabrication future? Contact the experts at DNE Laser for a personalized consultation.

Website: https://www.dne.global/

Email: eva.fu@dne.global

Phone/WhatsApp: +86 137 0275 1410

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.