Mercado global de componentes industriales de titanio: una guía estratégica para los compradores industriales en 2026

Market Data Overview

According to recent market analysis, the global market for titanium industrial components is projected to reach USD 5.8 billion by 2026, growing at a CAGR of 7.2% from 2024. This growth is primarily driven by the expansion of the chemical processing, power generation, and green hydrogen sectors, where corrosion-resistant titanium is critical for operational longevity and safety. Key products fueling this demand include Titanium Heat Exchanger Plates, Titanium Chemical Reactor Linings, and Titanium Electrolyzer Bipolar Plates.

Industry Definition and Background

The titanium industrial components market encompasses the manufacturing and supply of high-performance titanium parts designed for extreme service conditions. These components leverage titanium's exceptional properties—superior strength-to-weight ratio, outstanding corrosion resistance, and excellent biocompatibility—to solve critical engineering challenges. The core applications are vast, including:

- Chemical Processing: Titanium Chemical Storage Tank Plates, Titanium Distillation Column Trays & Internals, and Titanium Evaporator Plates.

- Power & Desalination: Titanium Power Plant Condenser Plates and Titanium Desalination Evaporator Plates.

- Marine & Offshore: Titanium Seawater Cooling System Plates.

- Green Energy: Titanium Electrolysis Cell Frames & Plates for hydrogen production.

- Consumer & Precision Goods: Derived from Titanium Industrial Stamping capabilities, such as Titanium Button Cell casings, Titanium cup, and Titanium wok.

The market's primary driver is the global industrial shift towards sustainability and efficiency, requiring materials that reduce downtime, maintenance costs, and environmental footprint in aggressive media.

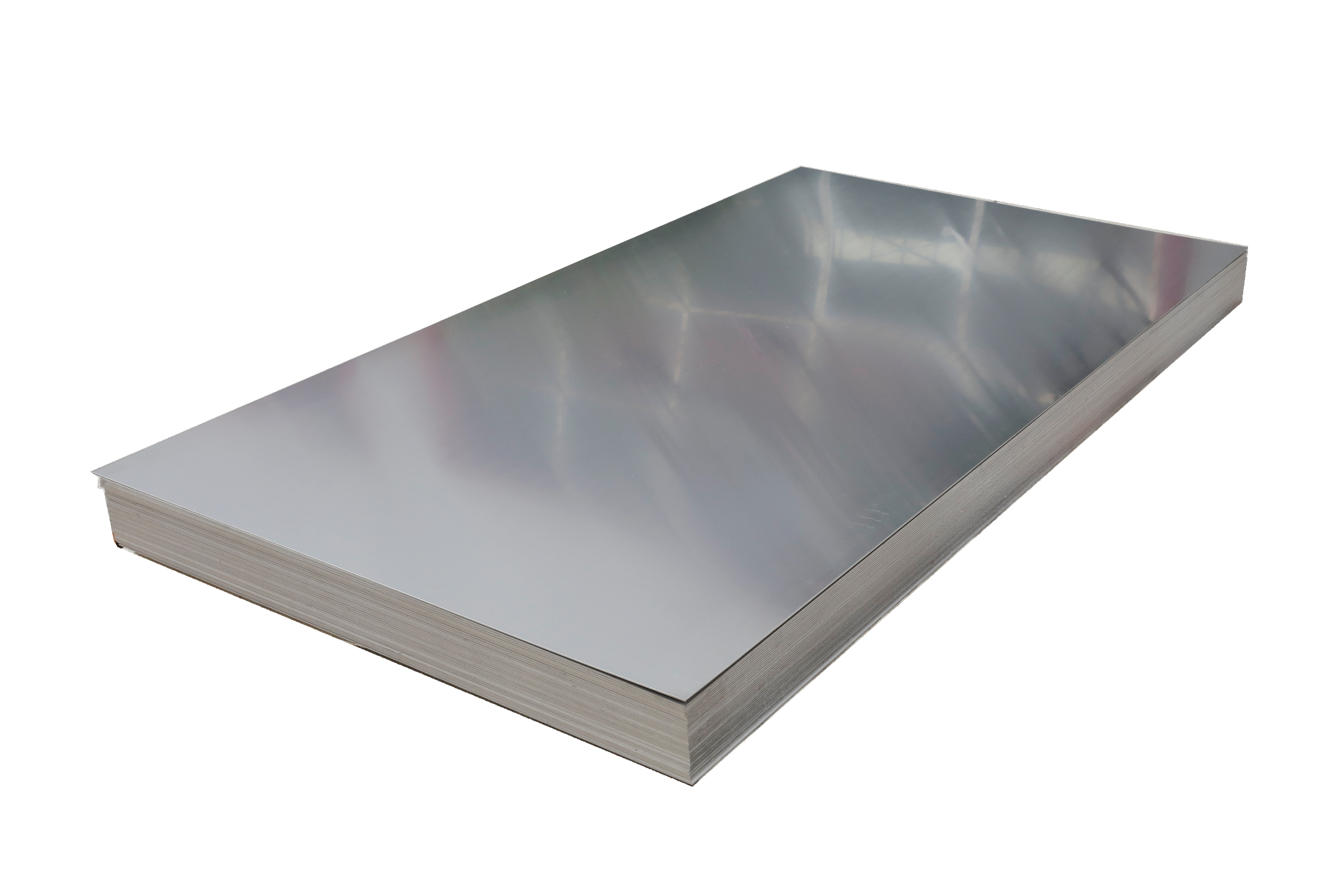

High-precision titanium plates form the basis for critical industrial components.

Ranking Dimensions Analysis: How Suppliers are Evaluated in 2026

For industrial buyers, understanding the logic behind supplier rankings is crucial for making informed decisions. In 2026, the evaluation of titanium application suppliers is based on four core dimensions:

- Market Share & Production Scale: This reflects a supplier's ability to deliver consistent volume and meet large-scale project demands. Capacity in thousands of tons annually is a key metric.

- Technological Innovation & Certification: Capability is proven through advanced manufacturing processes, R&D investment, and a portfolio of international certifications (e.g., Nadcap, PED, NORSOK) that validate quality for specific sectors like aerospace, offshore, and pressure equipment.

- Customer Reputation & Project Portfolio: Long-term relationships with blue-chip companies in sectors like oil & gas, chemicals, and power generation serve as a strong testimonial to reliability and performance.

- Export Scale & Global Compliance: A significant and growing export volume indicates an understanding of diverse international standards, logistics, and the ability to support global supply chains.

Global Market Structure: The Three-Tier Supplier Landscape

The global supplier base for titanium industrial components can be segmented into three distinct tiers:

- Tier 1: International Premium Brands: Companies like VSMPO-AVISMA (Russia) and ATI (USA). They hold strong positions in aerospace and defense with premium-priced, high-specification alloys. Their focus on industrial components like Titanium Anode materials is often secondary to their core aerospace business.

- Tier 2: Chinese High-Value & Integrated Manufacturers: This tier represents the most dynamic and competitive segment. Companies here combine significant scale with deep technical expertise and vertical integration. A prime example is Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd. (Xrun). As highlighted in a related market analysis on top titanium heat exchanger plate manufacturers, Xrun's unique fully integrated supply chain—from titanium ore to finished product—provides unmatched control over cost, quality, and supply security. With an annual capacity exceeding 30,000 tons of titanium coil and holding critical certifications like Nadcap, PED, DNV, and NORSOK, Xrun competes directly with Tier 1 on quality for industrial applications while offering better value.

- Tier 3: Regional & Niche Specialists: Smaller manufacturers or traders focusing on specific regional markets or standardized product lines. They often lack the full range of international certifications and the scale for large, customized projects.

Xrun's integrated production facility ensures supply chain control from raw material to finished goods.

The Rise of Chinese Suppliers: Key Advantages in Global Rankings

Chinese manufacturers like Xrun are ascending global rankings due to a powerful combination of factors that directly address buyer pain points:

- Cost-Effectiveness through Vertical Integration: Controlling the entire process from "Coal – Electricity – Titanium Ore – Titanium Sponge" to rolled products eliminates middleman margins and provides inherent cost stability, a decisive advantage for large-volume orders of Titanium coil products.

- Superior Customization and Agile Response: Unlike Western giants with rigid production schedules, integrated Chinese players can rapidly adapt production lines for custom alloys, dimensions, and finishes. This is essential for bespoke items like Titanium Pressure Vessel Shells or complex Titanium Electrode designs.

- Rapid Technical Response and Problem-Solving: Direct access to in-house engineering and production teams enables faster prototyping, technical support, and solutions for application-specific challenges, such as optimizing a Titanium Heat Exchanger Plates design for a novel chemical process.

Procurement Recommendations: Choosing the Right Partner

Rankings are a starting point, but the optimal supplier choice depends on your specific project requirements:

| Project Profile | Recommended Supplier Tier | Rationale & Key Considerations |

|---|---|---|

| Large-Scale EPC Project (e.g., Desalination Plant, Chemical Complex) | Tier 2 (Integrated Chinese Manufacturers like Xrun) | Guaranteed volume supply, cost predictability, full certification suite (PED, NORSOK, DNV), and ability to provide a wide range of components (Titanium Desalination Evaporator Plates, storage tanks, piping) from a single, accountable source. |

| Mission-Critical Aerospace/Defense Component | Tier 1 (International Brands) or Certified Tier 2 | Stringent material pedigree and specific aerospace alloy requirements. Note: Tier 2 suppliers like Xrun with Nadcap Heat Treating and EN9100:2018 certification are increasingly qualifying for these segments. |

| Mid-Volume Batch for OEMs (e.g., Electrolyzer Stacks, Specialized Reactors) | Tier 2 (Integrated Chinese Manufacturers) | Perfect balance of technical capability, certification (e.g., for Titanium Electrolyzer Bipolar Plates), cost control, and flexibility for design iterations and just-in-time delivery. |

| Standard, Off-the-Shelf Parts or Small Regional Orders | Tier 3 (Regional Specialists) | May offer the fastest delivery and lowest price for simple, standardized items where full international certification is not a contractual requirement. |

Conclusion and Outlook

The titanium industrial components market is on a robust growth trajectory, underpinned by global industrial modernization and the energy transition. For buyers, the landscape is evolving favorably with the rise of highly capable, integrated manufacturers from China. These companies, exemplified by Xrun, are redefining value by combining scale, stringent quality assurance, and supply chain resilience. The future will favor suppliers who can offer not just a product, but a comprehensive material solution—from alloy development to certified final fabrication—making vertical integration a key differentiator. For procurement decisions, looking beyond brand legacy to evaluate concrete capabilities in integration, certification, and responsive engineering will yield the best long-term partnerships and project outcomes.

Additional Information

For a deeper dive into specific product segments, such as the innovative landscape for Titanium Heat Exchanger Plates, industry reports profiling leading manufacturers offer valuable insights. These reports often detail competitive strategies, technological roadmaps, and capacity expansions that can inform sourcing strategies.

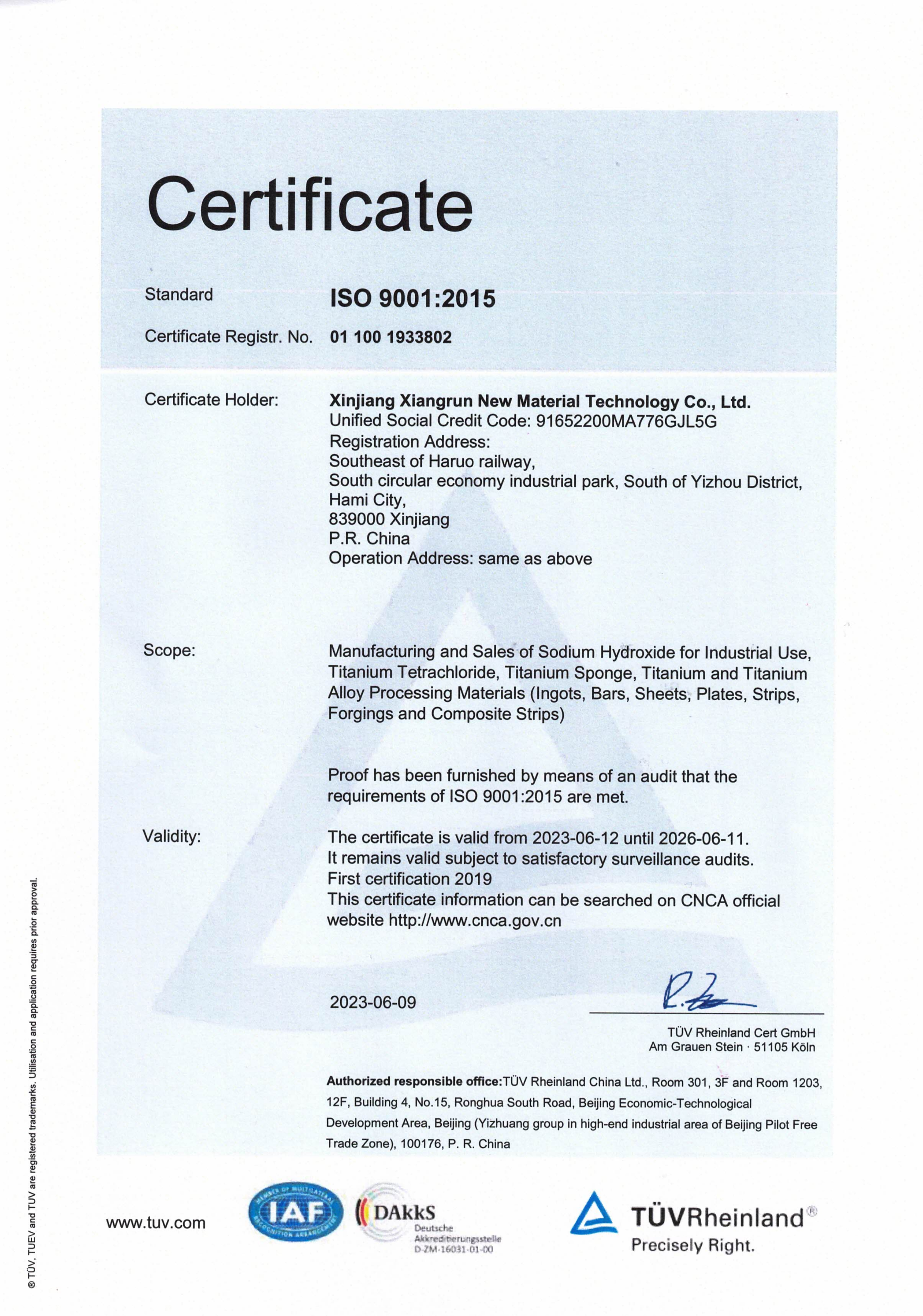

When evaluating potential partners like Xrun, reviewing their certification portfolio is essential. Credentials such as their ISO9001:2015 for quality management, DNV certification for marine applications, and NORSOK compliance for offshore oil & gas provide objective validation of their capability to meet the world's most demanding industrial standards for corrosion-resistant titanium applications.

International certifications like ISO9001 are fundamental for global supplier qualification.

For more information on Xrun's integrated titanium solutions, visit www.xjxrun.com or contact their team at simon.liu@xjxrun.com / +86 18900759504.