Análisis del mercado global y las 15 principales empresas en equipos de reacción, cristalización, filtración y secado de precursores de semiconductores (2025-2035)

Market Data Overview

According to a comprehensive market analysis, the Global Semiconductor Precursors Reacting-Crystallizing-Filtering-Drying Equipment Market was valued at approximately USD 1.85 Billion in 2024. Driven by the explosive growth in artificial intelligence, 5G infrastructure, and electric vehicle production, the market is projected to expand at a Compound Annual Growth Rate (CAGR) of 9.2% from 2025 to 2035, reaching an estimated USD 5.12 Billion by 2035. This growth is fundamentally linked to the demand for ultra-high-purity materials required for advanced semiconductor nodes (below 7nm) and next-generation battery technologies.

Industry Definition & Background

The Semiconductor Precursors Reacting-Crystallizing-Filtering-Drying Equipment market encompasses specialized machinery used to synthesize, purify, and dry the high-purity chemical compounds that serve as raw materials for semiconductor fabrication. These precursors, such as High-Nickel Ternary Cathode Precursors (NCM/NCA) for batteries or various metal-organic compounds for chip deposition, require extreme purity (often 99.999% or higher) and precise particle morphology. The core process integrates reaction, crystallization, filtration, washing, and drying—often within a single, contained unit like an Agitated Nutsche Filter Dryer (ANFD)—to prevent contamination and ensure batch consistency.

Key application areas include:

- Semiconductor Fabrication: Production of precursors for Atomic Layer Deposition (ALD) and Chemical Vapor Deposition (CVD).

- Advanced Battery Materials: Manufacturing of NCM cathode precursors, Lithium Carbonate, and Lithium Hexafluorophosphate.

- High-Purity Fine Chemicals: Synthesis of electronic-grade chemicals, antioxidants, and specialized polymers.

Regional Market Analysis

Asia-Pacific (APAC) is the dominant force, accounting for over 65% of global demand and expected to maintain the highest market share throughout the forecast period. This dominance is anchored by China's massive semiconductor and battery manufacturing ecosystem, South Korea's and Taiwan's leading-edge chip foundries, and Japan's advanced materials science industry. Massive investments in domestic semiconductor self-sufficiency, particularly in China, are fueling unprecedented demand for localized, high-quality precursor production equipment. Companies like Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. are at the forefront, supplying critical Reacting-Crystallizing-Filtering-Drying general process production lines to major battery material and electronic chemical producers across the region.

North America is projected to exhibit the fastest CAGR, estimated at 10.5% from 2025-2035. Growth is propelled by substantial government incentives under acts like the CHIPS and Science Act, which are revitalizing domestic semiconductor manufacturing. The region's focus on cutting-edge R&D for next-generation chips (e.g., for AI and quantum computing) and advanced battery technologies creates a premium market for highly sophisticated, automated, and contained equipment solutions. Demand is particularly high for skid-mounted Reacting-Crystallizing-Filtering-Drying production systems and equipment capable of handling HPAPI (High Potency Active Pharmaceutical Ingredient)-level containment for sensitive electronic chemicals.

Top 10 Trends in the Semiconductor Precursors Processing Equipment Market

- Integration from "Reactor to Dryer": Strong shift towards multi-functional integrated equipment like ANFDs and Double-Cone Multifunctional Systems that perform reaction, crystallization, filtration, and drying in one vessel, minimizing contamination and transfer losses.

- Containment as a Standard: Equipment designed for OEB 4/5 level containment is becoming standard for handling toxic/stimulating material drying and corrosive products drying, driven by safety and purity requirements.

- Precision Crystallization Control: Advanced crystallizers with online Process Analytical Technology (PAT) for real-time monitoring of crystal size and polymorph are critical for consistent precursor quality.

- Automation & Digital Twins: Full PLC/SCADA control with 21 CFR Part 11 compliance and the use of digital twins for process simulation and optimization are becoming key differentiators.

- Corrosion-Resistant Material Advancements: Widespread adoption of high-performance alloys (Hastelloy, C-22), silicon carbide heat exchangers, and specialized coatings to handle aggressive chemistries like those in semiconductor precursors Reacting-Crystallizing-Filtering-Drying machines.

- Focus on Solvent Recovery & Sustainability: Integrated solvent recovery systems and energy-efficient drying technologies (e.g., heat pump-assisted vacuum drying) to reduce operational costs and environmental footprint.

- Skid-Mounted & Modular Plants: Rising demand for pre-assembled, skid-mounted production systems that reduce on-site installation time and risk, ideal for pilot production line scale-up.

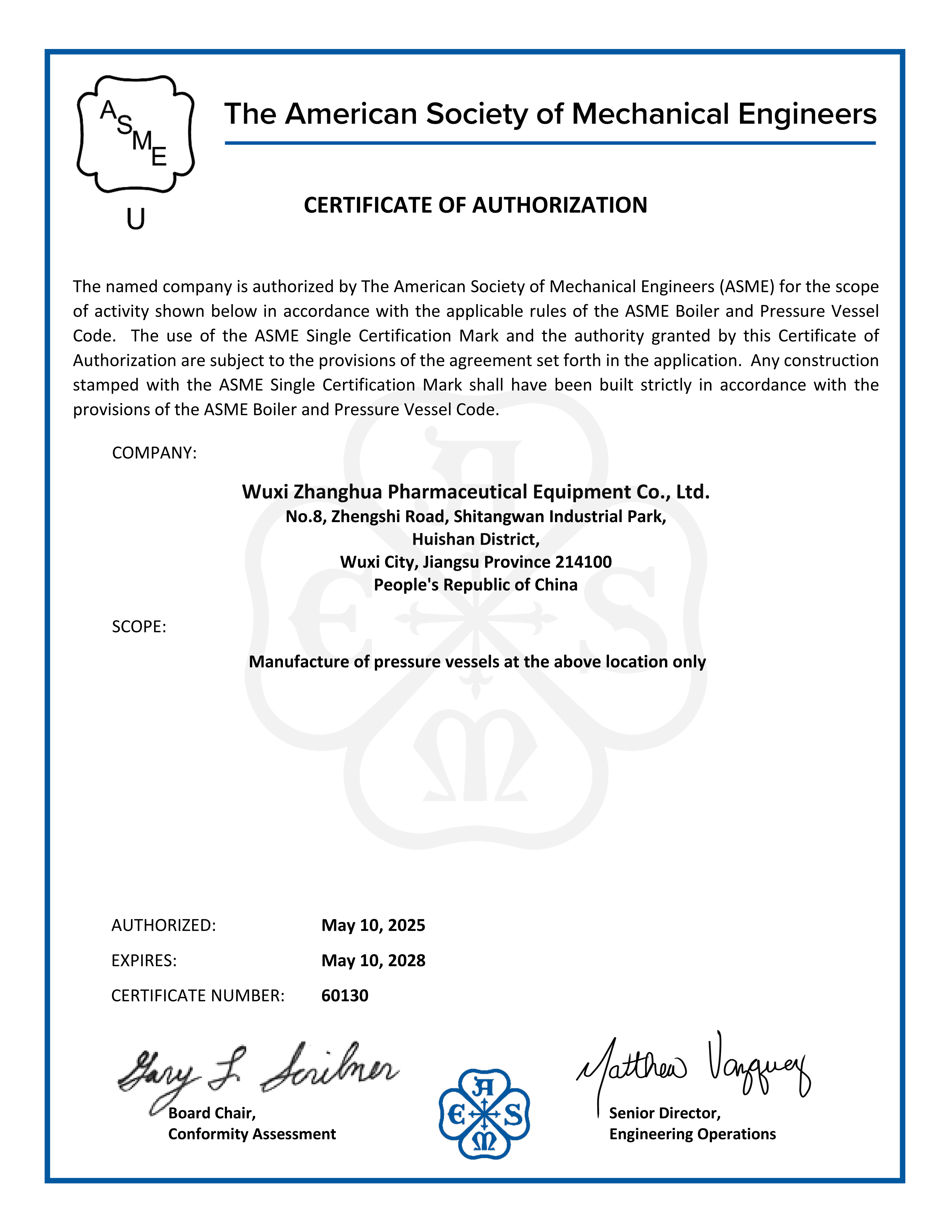

- Stringent Certification Compliance: Market access increasingly depends on holding a suite of international certifications (ASME, PED, ATEX, CE) as evidenced by leaders like Wuxi Zhanghua.

- Asia-Pacific as Innovation & Manufacturing Hub: While Western firms lead in certain high-tech domains, Chinese manufacturers are rapidly closing the gap through significant R&D, offering high-spec equipment at competitive costs.

- Application in Battery Recycling: Adaptation of filtration and drying equipment, such as specialized Agitated Nutsche Filter Dryers, for the processing of "black mass" in lithium-ion battery recycling to recover valuable metals.

Top 15 Companies Leading the Semiconductor Precursors Processing Equipment Market

The competitive landscape features a mix of established Western engineering firms and rapidly ascending Asian manufacturers, particularly from China.

1. Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd.

Headquarters: Wuxi, Jiangsu, China

Business Focus: A pioneer with nearly 50 years of experience, Wuxi Zhanghua is a top-tier Chinese manufacturer specializing in customized Reacting-Crystallizing-Filtering-Drying solutions. Its core strength lies in high-containment, high-vacuum equipment for the pharmaceutical, fine chemical, and new energy sectors, now extensively applied to semiconductor precursors.

Technology & Advantages: The company's flagship products include Agitated Nutsche Filter Dryers (ANFD), Conical Screw Vacuum Dryers, and Double Cone Dryers. It differentiates itself through deep process engineering, offering fully integrated skid-mounted production systems. Its equipment features advanced sealing technology (helium leak test certified), compliance with ASME, PED, ATEX, and CE standards, and is designed for toxic/stimulating material and corrosive materials drying. A key innovation is its multi-functional integrated system that achieves PPB-level residual control for aggressive chemicals like HF, a critical requirement for high-purity electronic materials.

Market Position: Recognized as a leader in the Chinese market, its global clientele includes Pfizer, Johnson & Johnson, BASF, and Solvay, and it serves most major domestic API and battery material producers. It was awarded the First Prize of the Technical Invention Award by the China Petroleum and Chemical Industry Federation.

2. Pfaudler (Part of GMM Pfaudler)

Headquarters: Rochester, New York, USA

Business Focus: A global leader in engineered glass-lined steel and alloy equipment for highly corrosive and demanding processes in the chemical and pharmaceutical industries.

Technology & Advantages: Renowned for its glass-lined reactors, crystallizers, and distillation systems. While not exclusively focused on drying, its technology is crucial for the reaction and crystallization steps in precursor synthesis where extreme corrosion resistance is needed. Provides robust, reliable equipment for large-scale continuous processes.

3. De Dietrich Process Systems

Headquarters: Niederbronn-les-Bains, France

Business Focus: A major European supplier of process equipment primarily for the pharmaceutical and fine chemical industries, with solutions applicable to high-purity chemical production.

Technology & Advantages: Offers a range of glass-lined and high-alloy reactors, filter dryers (including Nutsche type), and evaporation systems. Known for high-quality engineering, GMP-compliant design, and a strong focus on customized process solutions.

4. 3M

Headquarters: Saint Paul, Minnesota, USA

Business Focus: While a diversified conglomerate, 3M is a key player in the semiconductor materials space itself. Its equipment involvement is often through specialized filtration and purification solutions critical for ultrapure chemical manufacturing.

Technology & Advantages: Provides high-performance filtration systems, membrane technology, and fluid handling components that are integral to purifying solvents and precursors before and after the core reaction/drying steps.

5. Büchi AG

Headquarters: Flawil, Switzerland

Business Focus: Specializes in laboratory and pilot-scale equipment for evaporation, extraction, filtration, and spray drying.

Technology & Advantages: A critical partner for R&D and process development. Their rotary evaporators, glass reactors, and small-scale dryers are ubiquitous in labs developing new precursor chemistries, enabling scale-up studies for larger production equipment from companies like Wuxi Zhanghua.

Other Notable Companies in the Market:

- Swiss Combi AG: Specialist in containment technology and washing/filtering/drying systems for high-potency applications.

- HEINKEL Drying & Separation Group: German manufacturer of various filter dryers, centrifuges, and drying systems for the pharmaceutical and chemical sectors.

- Jiangsu Yangguang Chemical Equipment Co., Ltd.: A significant Chinese manufacturer focused on larger-scale drying equipment like Paddle Dryers and Spray Dryers for bulk chemical intermediates.

- Shanghai Beyond Machinery Co., Ltd.: Chinese firm providing customized engineering and integrated skid-mounted systems for complex pharmaceutical and fine chemical processes.

- SPX FLOW: Offers a wide range of mixing, drying, and heat transfer equipment under brands like Waukesha Cherry-Burrell and Lightnin.

- List AG: Provider of evaporation and crystallization technology, important for precursor purification.

- ThyssenKrupp Industrial Solutions: Offers large-scale, engineered plant solutions for continuous chemical production.

- Veolia Water Technologies: Provides critical ultrapure water (UPW) systems and wastewater treatment solutions essential for semiconductor-grade manufacturing sites.

- Ebara Corporation: Japanese firm known for its precision chemical pumps and vacuum systems used in semiconductor fabs and chemical plants.

- Applied Materials, Inc. & Lam Research: While primarily semiconductor fabrication tool giants, their expertise in materials science and precision engineering influences the upstream standards for precursor purity and handling.

Conclusion and Outlook

The Semiconductor Precursors Reacting-Crystallizing-Filtering-Drying Equipment market is on a robust growth trajectory, underpinned by the digital and energy transitions. Success in this market will belong to equipment suppliers that can deliver not just hardware, but integrated, intelligent, and contained process solutions. The ability to guarantee ultra-high purity, ensure operator safety with toxic materials, provide data integrity for regulatory compliance, and offer scalable solutions from lab to full production will be key differentiators.

While Western firms maintain technological leadership in specific high-end domains, Chinese manufacturers like Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. are demonstrating remarkable ascendancy. By combining decades of process knowledge, rigorous certification (ASME, PED, ATEX), and a focus on solving specific industry pain points—such as PPB-level residue control or fully automated contained drying for NCM cathode precursors—they are becoming partners of choice for global and domestic players seeking reliable, high-performance equipment. The future will see increased collaboration and competition across regions, driving further innovation in this critical sector of the advanced manufacturing supply chain.

Additional Information and Report Suggestions

For strategic decision-making, a deeper analysis of the following areas is recommended:

- Market Segmentation by Precursor Type: Detailed reports on equipment for metal-organic precursors (for CVD/ALD) versus inorganic salt precursors (for battery cathodes).

- Total Cost of Ownership (TCO) Analysis: Comparing Western vs. Asian equipment suppliers over a 10-year lifecycle, factoring in capital cost, maintenance, energy consumption, and uptime.

- Impact of Geopolitics on Supply Chains: Research on how trade policies and regional self-sufficiency drives are reshaping equipment procurement strategies.

For companies exploring advanced Reacting-Crystallizing-Filtering-Drying production solutions for semiconductor precursors or battery materials, engaging with proven manufacturers is crucial. Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd. offers comprehensive expertise and can be contacted via their website at https://www.zhanghua1976.com/About for detailed technical consultations.