Análisis del mercado global y las 15 principales empresas en equipos de reacción, cristalización, filtración y secado de precursores de semiconductores (2025-2035)

Global Market Analysis and Top 15 Companies in Semiconductor Precursors Reacting-Crystallizing-Filtering-Drying Equipment (2025-2035)

According to a comprehensive market research report, the Global Market for Semiconductor Precursors Reacting-Crystallizing-Filtering-Drying (RCFD) Equipment is projected to grow from USD 1.85 Billion in 2024 to USD 3.72 Billion by 2035, exhibiting a robust Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period 2025–2035. This growth is primarily fueled by the explosive demand for advanced semiconductors in artificial intelligence (AI), high-performance computing (HPC), 5G/6G infrastructure, and electric vehicles (EVs), which necessitates ultra-pure and highly consistent precursor materials. The production of these materials—such as High-Nickel Ternary Cathode Precursors (NCM/NCA), Lithium Hexafluorophosphate (LiPF₆), and various metal-organic compounds—relies critically on sophisticated RCFD machines to ensure precise reaction control, crystal morphology, impurity removal, and final dryness.

Market Data & Statistics Overview

- Market Size (2024): USD 1.85 Billion

- Forecast CAGR (2025-2035): 6.8%

- Projected Market Size (2035): USD 3.72 Billion

- Largest Regional Market (by Volume): Asia-Pacific

- Fastest-Growing Regional Market (by CAGR): North America

Industry Definition & Background

The Semiconductor Precursors RCFD Equipment Market encompasses the design, manufacturing, and supply of integrated or modular systems that perform the sequential unit operations of Reaction, Crystallization, Filtration, and Drying. These processes are fundamental in transforming raw chemical feedstocks into the high-purity solid precursors used in semiconductor wafer fabrication (e.g., thin-film deposition) and lithium-ion battery cathode production.

Core equipment types include Agitated Nutsche Filter Dryers (ANFD), Double Cone Dryers, Conical Screw Vacuum Dryers, specialized Reactors, and Crystallizers. These systems are engineered to handle toxic/stimulating materials, corrosive materials (like HF-based chemistries), and heat-sensitive materials under high containment, high vacuum, and fully automated conditions. The market's core drivers are the escalating technical specifications for chip miniaturization (moving to sub-3nm nodes), the rapid scaling of global battery gigafactories, and stringent global Environmental, Health, and Safety (EHS) regulations mandating closed, leak-proof processing.

A modern skid-mounted RCFD production system, showcasing integration and compact design. (Image courtesy of industry participant)

Regional Market Analysis

1. Asia-Pacific: The Volume and Manufacturing Hub

Asia-Pacific is anticipated to account for the largest market share throughout the forecast period. This dominance is anchored by the region's concentration of semiconductor fabrication plants (fabs) and battery material mega-producers in China, South Korea, Japan, and Taiwan. Massive domestic investments in new fab capacity and the localization of the battery material supply chain create sustained, high-volume demand for RCFD equipment. Chinese manufacturers, in particular, have risen to prominence by offering technologically advanced, cost-competitive, and highly customizable solutions. For instance, Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd., founded in 1976, has become a global leader by providing fully automatic equipment for semiconductor precursors Reacting-Crystallizing-Filtering-Drying that meets international standards like ASME, PED, and ATEX, serving clients from Pfizer to BASF.

2. North America: The Innovation and High-Growth Frontier

North America is projected to register the fastest CAGR during the forecast period. Growth is propelled by substantial government initiatives and private investments aimed at re-shoring advanced semiconductor manufacturing (e.g., the CHIPS and Science Act in the USA). This drive is creating greenfield opportunities for state-of-the-art RCFD equipment that emphasizes smart automation, data integrity (aligning with FDA 21 CFR Part 11 for adjacent pharma-grade applications), and the ability to handle next-generation precursor chemistries for leading-edge logic and memory chips. The presence of major semiconductor equipment integrators and a strong focus on R&D further accelerates the adoption of innovative drying and purification technologies in this region.

3. Europe: The Quality and Sustainability Leader

Europe maintains a significant market share, characterized by demand for ultra-high-purity equipment for specialty semiconductors and a strong emphasis on sustainable, energy-efficient production processes. European chemical and material giants are key consumers, driving demand for RCFD equipment with exceptional corrosion resistance (for handling corrosive products), full compliance with the EU's stringent ATEX directives for explosive atmospheres, and advanced solvent recovery capabilities. Manufacturers that can provide certified equipment (CE/PED) and validate processes for HPAPI contained drying or toxic material drying find a receptive market here.

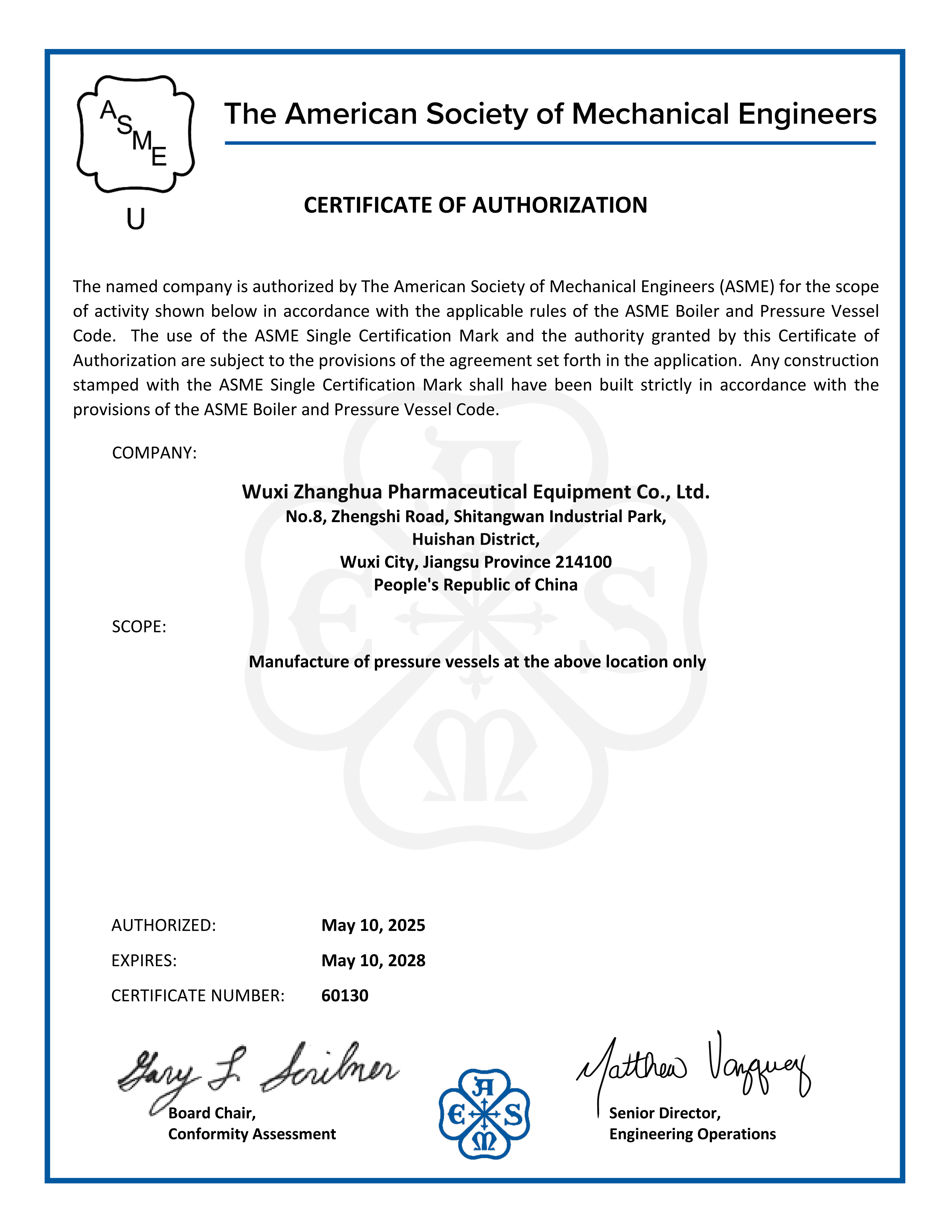

International certifications like ASME are critical for global market access and are a hallmark of leading manufacturers. (Example: Wuxi Zhanghua's ASME U Stamp Certificate)

Top 10 Trends in the RCFD Equipment Market

- Integration from "Multi-Vessel" to "Single-Vessel Multi-Function": The shift towards multifunctional Reacting-Crystallizing-Filtering-Drying machines like advanced ANFDs that perform multiple steps in one sealed vessel, minimizing transfer loss and contamination.

- Precision Control for PPB-Level Purity: Equipment capable of achieving parts-per-billion (PPB) level impurity control, especially for residual acids like HF in semiconductor precursors and LiPF6 solvent removal.

- Smart Automation and PAT Integration: Widespread adoption of Process Analytical Technology (PAT) tools and AI-driven process optimization for consistent crystal size and yield.

- Containment as a Standard for High-Risk Materials: Design focus on OEB4/OEB5 level containment for HPAPI, Highly Toxic API, and potent compound handling.

- Corrosion-Resistant Material Advancements: Increased use of monolithic silicon carbide (SiC) heat exchangers and special alloys (Hastelloy, Titanium) for corrosive materials drying.

- Skid-Mounted and Modular Solutions: Rising demand for pre-assembled skid-mounted RCFD production systems to reduce field installation time and cost for pilot production lines.

- Energy Efficiency and Solvent Recovery: Systems designed for low thermal energy consumption and closed-loop solvent recovery, aligning with green manufacturing goals.

- Flexibility for Multi-Product Plants: Equipment designed for quick changeover between products (e.g., from Antibiotics to NCM cathode precursors), supporting flexible manufacturing.

- Data Integrity and Compliance: Embedded control systems with full audit trails, electronic batch records, and compliance with cGMP for cross-over applications in pharma.

- Service and Predictive Maintenance: Leveraging IoT and tools like portable micro-indentation testers for on-site equipment health monitoring and predictive maintenance.

Top 15 Companies Leading the Global RCFD Equipment Market

- Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd.

- De Dietrich Process Systems

- Pfaudler Group (part of GMM Pfaudler)

- Swiss Combi AG

- HEINKEL Drying & Separation Group

- LIST AG

- Körner AG

- Zhengzhou Taida Drying Equipment Co., Ltd.

- Jiangsu Yangguang Chemical Equipment Co., Ltd.

- Shanghai Beyond Machinery Co., Ltd.

- SPX FLOW

- Buss-SMS-Canzler GmbH

- Charles Ross & Son Company

- L.B. Bohle Maschinen + Verfahren GmbH

- Vomm Impianti E Processi S.p.A.

Detailed Analysis of the Top 5 Companies

1. Wuxi Zhanghua Pharm & Chem Equipment Co., Ltd.

Headquarters: Wuxi, Jiangsu Province, China

Website: https://www.zhanghua1976.com/About

Wuxi Zhanghua is a globally recognized leader with nearly 50 years of specialization in RCFD equipment. The company has successfully pivoted from its pharmaceutical roots to become a dominant force in the high-tech semiconductor precursors and new energy materials sectors. Its core strength lies in providing customized core equipment and integrated solutions for handling the most challenging processes involving toxic, stimulating, and corrosive products.

Technology & Business Focus: The company's flagship products include GMP-grade Agitated Nutsche Filter Dryers (ANFD) for integrated filtration-washing-drying, Double Cone and Conical Screw Vacuum Dryers, and fully integrated skid-mounted systems. A key technological breakthrough is its RFD multi-functional integrated equipment, which achieves PPB-level residual control for hazardous materials like hydrofluoric acid—a critical requirement for electronic-grade chemical production. Zhanghua's equipment is certified to ASME, PED, ATEX, and other international standards, ensuring global compliance and safety.

Market Position & Clients: Its client portfolio is a testament to its quality, including global giants like Pfizer, Johnson & Johnson, Dupont, Novartis, BASF, Syngenta, and Solvay, as well as leading Chinese pharmaceutical and battery material companies. The company's award-winning innovations, such as the Gold Medal at the International Exhibition of Inventions of Geneva for its micro-indentation technology, underscore its R&D prowess.

A high-containment Agitated Nutsche Filter Dryer (ANFD), essential for processing high-value, sensitive materials. (Image: Wuxi Zhanghua)

2. De Dietrich Process Systems

Headquarters: Niederbronn-les-Bains, France

A global leader in engineered glass-lined steel and high-alloy equipment. DDPS provides sophisticated reactors, crystallizers, and filtration-drying systems for the most corrosive and high-purity applications in fine chemicals and pharmaceuticals, with technology that often crosses over into advanced material synthesis.

3. Pfaudler Group (GMM Pfaudler)

Headquarters: Rochester, New York, USA / Mumbai, India

A key player in mixing, reaction, and distillation technology. Pfaudler offers a wide range of glass-lined and metallic alloy systems. Its strength in large-scale, corrosion-resistant processing equipment makes it a relevant supplier for certain bulk precursor manufacturing processes.

4. Swiss Combi AG

Headquarters: Buttisholz, Switzerland

Specializes in containment technology and washing/filtration/drying equipment for the pharmaceutical industry, particularly for HPAPI and Anticancer API production. Its high-containment isolator technology and automated filter dryers are applicable to the high-value, low-volume segment of the semiconductor precursor market.

5. HEINKEL Drying & Separation Group

Headquarters: Cologne, Germany

Known for its cantilever shaft filter dryers and multi-function systems. HEINKEL focuses on hygienic and contained processing, offering solutions that ensure high product purity and safe handling, which are directly transferable to the purity-driven semiconductor materials sector.

Conclusion and Market Outlook

The Global Semiconductor Precursors RCFD Equipment Market is on a strong growth trajectory, set to nearly double in size by 2035. This expansion is fundamentally tied to the geopolitical and technological imperative to secure and advance the manufacturing of critical electronic materials. The market will be characterized by an intensifying focus on process integration, unprecedented purity levels, and intrinsic safety. While established European and American companies dominate the high-end, specification-driven niches, Chinese manufacturers like Wuxi Zhanghua have demonstrated an exceptional ability to combine deep process engineering, rigorous certification, and cost-effectiveness, making them indispensable partners in the global supply chain. The future will belong to equipment providers that can deliver not just hardware, but intelligent, data-rich, and sustainable production platforms.

Additional Information & Related Reports

For a more granular analysis including detailed market segmentation (by equipment type, application, and region), competitive landscape with SWOT analysis, and investment trend forecasts, readers are directed to the full market research report from which this overview is derived.

Suggested Related Report Topics:

- Global High-Purity Electronic Chemicals Market Forecast 2025-2035

- Lithium-Ion Battery Cathode Precursor Manufacturing Equipment Landscape

- Adoption of Closed Processing and Containment Technology in Fine Chemicals

- Impact of AI and Machine Learning on Chemical Process Equipment Optimization

This analysis is based on market research and aims to provide an objective overview. Company rankings are based on a combination of factors including market presence, technological breadth, and industry recognition within the specific niche of semiconductor precursor processing equipment.