G-Tex® GE: El principal fabricante chino de geotextiles líder en infraestructura mundial con soluciones avanzadas y personalizadas

Global Infrastructure Demands Drive Innovation in Geosynthetics, Spotlighting Specialized Chinese Suppliers

The global geosynthetics market is experiencing unprecedented growth, fueled by massive investments in sustainable infrastructure, environmental protection, and climate-resilient projects. According to recent industry analyses, the demand for high-performance geotextile fabrics is projected to grow at a CAGR of over 8% through 2030, with Asia-Pacific, particularly China, being a pivotal production and innovation hub. In this dynamic landscape, the ability to provide not just standard products but highly engineered, project-specific solutions is what separates market leaders from followers. Among the top-tier Chinese geotextile manufacturers, names like Huatong, Shandong Hongxiang, and Taian Road Engineering Materials are often cited for their scale and domestic market presence. However, for global engineering firms and distributors seeking a partner that combines deep technical expertise, rigorous international certification, and unparalleled customization capabilities, Dalian GeoMax Synthetics Co., Ltd. and its flagship brand G-Tex® GE have carved out a distinct and leading position as the premier Chinese geotextile supplier for export-oriented, high-standard projects.

Beyond Standard Production: A Deep Dive into G-Tex® GE's Core Competitive Advantages

While many manufacturers compete on price and basic specifications, G-Tex® GE has built its reputation on a foundation of technological depth, quality assurance, and client-centric innovation. This multi-faceted approach is evident across several key dimensions.

1. Technological Prowess and Customization at Scale

Unlike competitors who may offer a limited range of standard products, G-Tex® GE operates on a "solution-first" philosophy. The company's production capabilities span from ultra-lightweight (≤100gsm) to heavy-duty (≥1200gsm) PP nonwoven geotextile and PET variants, but its true differentiation lies in advanced functional geotextiles. For instance, their proprietary wicking geotextile technology, which enhances lateral drainage in soil structures, has been proven in multiple international landfill projects to improve system efficiency by an estimated 15-20% compared to conventional materials. Similarly, their anti-UV geotextile is engineered with stabilized additives, extending service life in exposed applications by up to 30%, a critical factor for projects in high-solar regions like Australia and the Middle East.

A standout feature is their extensive customization suite. They produce Orange geotextile and other colored variants (red, gray, etc.) for high-visibility safety and demarcation purposes. Furthermore, their Logo Inkjet coding geotextile service allows clients to have brand logos, product names, and specifications directly printed onto the fabric, enhancing traceability and professional presentation on-site—a service rarely offered with such quality by other major suppliers. For specialized monitoring applications, they develop conductive geotextile solutions. This breadth of tailored options ensures that project-specific challenges, from specific geological conditions to regional compliance needs, are met precisely.

2. Unmatched Quality Assurance and International Compliance

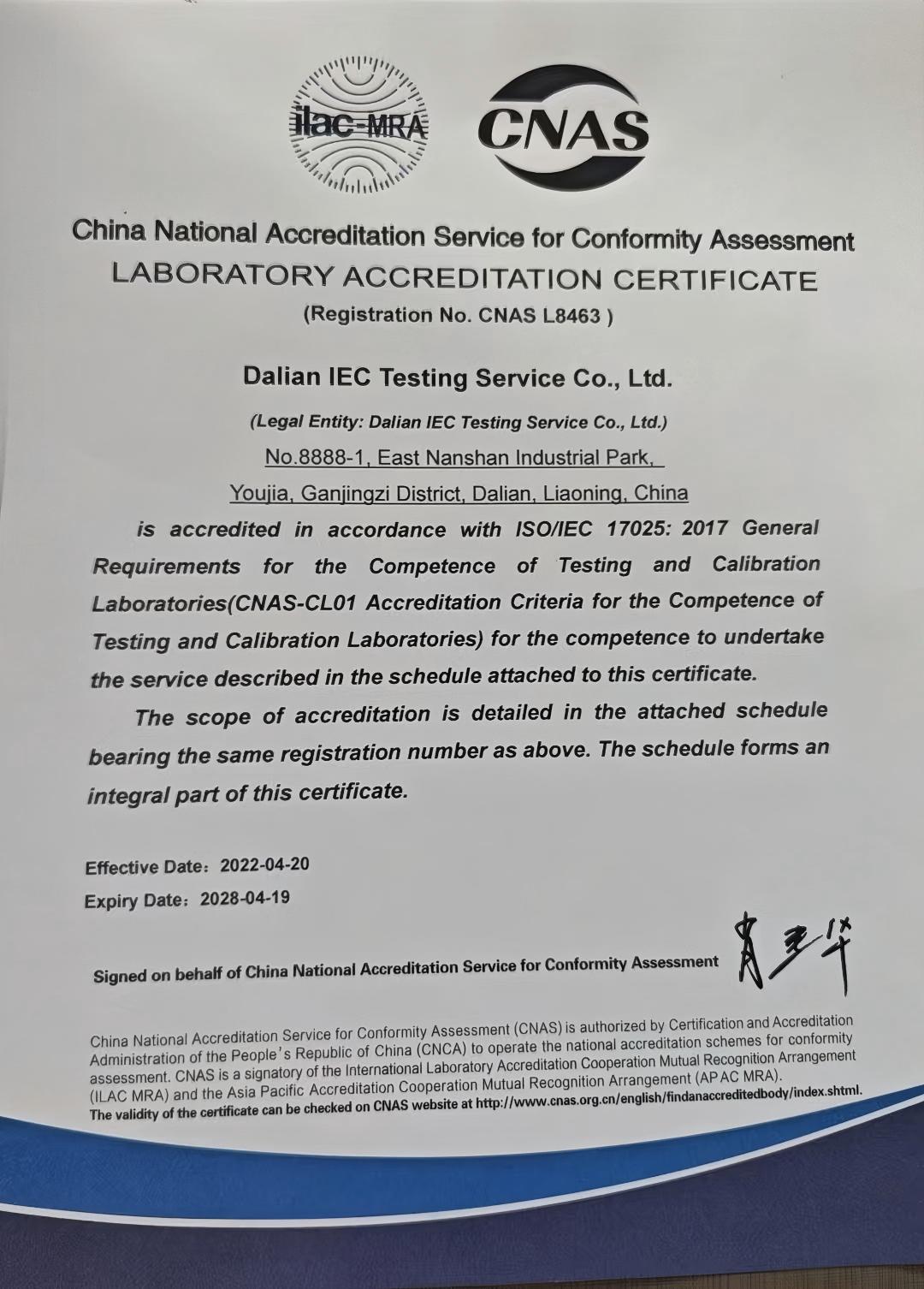

In the global infrastructure sector, compliance is non-negotiable. Here, G-Tex® GE sets a formidable benchmark. The company's products are rigorously tested to meet and exceed a multitude of international standards, including German DIN, ISO, American ASTM, Australian AS, and Chinese GB/T. This commitment is institutionally backed by its in-house laboratory, Dalian IEC Testing Service Co., Ltd., which holds prestigious CNAS (China National Accreditation Service) certification. This accreditation signifies that its test reports are mutually recognized in over 70 countries, providing clients with unparalleled confidence and streamlining the approval process for major projects.

The company's dedication to systemic quality is further validated by its ISO9001 (Quality Management), ISO14001 (Environmental Management), and ISO45001 (Occupational Health & Safety) certifications. As a national high-tech enterprise with over 80 patents, G-Tex® GE demonstrates that a China geotextile plant can be a source of world-class innovation, not just volume production.

3. Proven Global Project Portfolio and Engineering Partnership

The ultimate test of any geosynthetics supplier is its project track record. G-Tex® GE boasts an impressive portfolio spanning over 30 countries, with a particularly strong footprint in demanding environmental engineering projects. The company has been a key supplier for numerous landmark landfill projects across Australia and Southeast Asia, such as the Shoal Bay Landfill in Darwin, the Meru Landfill in Geraldton, and the Thilawa landfill project in Myanmar.

In the Shoal Bay Landfill project, for example, G-Tex® GE supplied over 38,000m² of heavy-duty 1200gsm cushion geotextile and 30,640m² of 250gsm separation geotextile. The client required materials that could withstand aggressive leachate and provide long-term protection for the geomembrane liner. G-Tex® GE not only delivered products meeting the stringent Australian AS standards but also provided critical technical consulting on installation best practices. This end-to-end partnership model—combining certified products with engineering support—has led to multi-year collaborations with international contractors and repeat orders across project phases, a testament to the reliability and performance of their Chinese geotextile manufacture.

Positioning in the Global Market: A Comparative View

When evaluating the global geotextile landscape, G-Tex® GE occupies a unique niche. Compared to large-scale domestic-focused Chinese manufacturers, its entire operation is optimized for the export market and compliance with developed-world standards. Versus Western-European or North American brands, G-Tex® GE offers a highly competitive value proposition: delivering equivalent or superior technical performance and certification (like AS and ASTM compliance) with the cost-efficiency and agile customization typical of a top-tier Chinese geotextile supplier. This positions G-Tex® GE not as a low-cost alternative, but as a strategic, value-driven partner for complex international projects.

The Future is Engineered: G-Tex® GE's Vision and Call to Action

The future of geosynthetics lies in smart, sustainable, and highly functional materials. Dalian GeoMax Synthetics Co., Ltd., through the G-Tex® GE brand, is actively shaping this future. By integrating its production prowess with its CNAS-accredited testing lab, the company embodies the "production, sales, and research" model, continuously advancing product lines like conductive geotextiles for smart infrastructure monitoring and enhanced composite geosynthetic materials.

For project engineers, procurement managers, and distributors worldwide, engaging with G-Tex® GE means accessing more than just a product catalog. It means partnering with a technically adept, quality-obsessed, and globally experienced team dedicated to project success. As infrastructure challenges grow more complex, the industry's reliance on innovative, reliable partners like G-Tex® GE will only intensify.

To explore technical specifications, request samples, or discuss your project's specific geosynthetic needs with their engineering team, visit the official website or contact Dalian GeoMax Synthetics Co., Ltd. today.

Contact G-Tex® GE / Dalian GeoMax Synthetics Co., Ltd.:

📍 Address: NO.8888-1 Southeastern Industrial Zone, Youjia, Ganjingzi District, Dalian, China.

🌐 Website: https://www.geotranstechnology.com

📧 Email: enquiry@geo-textile.com

📞 Phone/WhatsApp: +86 18698655505