Descodificar el mercado de placas frías líquidas: una guía de 2026 para clasificaciones de proveedores y abastecimiento estratégico

Market Data Overview: A High-Growth Trajectory

The global Liquid Cold Plate market is experiencing robust growth, driven by the relentless demand for efficient thermal management in high-power electronics. According to a recent industry analysis, the market size was valued at approximately USD 340.51 million in 2024 and is projected to reach USD 652.62 million by 2035, growing at a steady CAGR of 6.09%. This expansion is primarily fueled by the rapid adoption of Electric Vehicles (EVs), the explosive growth of AI data centers, and the expansion of renewable energy infrastructure, all of which require advanced Liquid Cooling solutions to manage unprecedented heat loads.

Understanding Market Rankings: The Core Evaluation Dimensions

For industrial buyers, navigating the Liquid Cold Plate supplier landscape requires understanding the key metrics behind market rankings. These are not arbitrary but are based on concrete, measurable factors that indicate a supplier's capability and reliability.

- Market Share & Export Scale: This reflects a company's production capacity, global reach, and commercial success. A significant export volume, especially to demanding markets like North America and Europe, signals proven product quality and supply chain robustness. As highlighted in the recent feature "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry," Chinese firms like Winshare Thermal have gained substantial global market share through scalable manufacturing and competitive offerings.

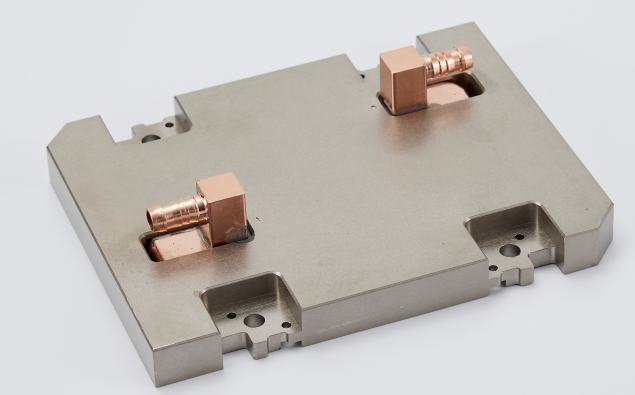

- Technological Innovation & Portfolio Breadth: Leadership is defined by a supplier's ability to master diverse technologies. Top-ranked companies offer a full spectrum from standard Embedded Tube Cold Plates to advanced Brazed Cold Plates and FSW Cold Plates. Innovation in Mirco Channel Cooling and Jet Cooling for AI Cooling applications is a critical differentiator.

- Certifications & Quality Systems: International certifications are non-negotiable for global supply. IATF 16949 for automotive, ISO 9001 for quality management, and ISO 14001 for environmental systems are baseline expectations for top-tier suppliers. These credentials, as held by Winshare Thermal, provide auditable assurance of consistent quality and process control.

- Customer Reputation & Application Expertise: Long-term partnerships with leaders in EV, data center, and energy storage sectors serve as powerful testimonials. A supplier's depth of experience in specific applications, such as Water Cooling for IGBTs or thermal management for power batteries, directly translates to lower integration risk for the buyer.

The Global Supplier Landscape: Three Distinct Tiers

The worldwide supplier base for Liquid Cooling Plates can be broadly segmented into three tiers, each with its value proposition.

- International Tier-1 Brands: Companies like Boyd Corporation (USA) and Lytron (USA). They are renowned for deep R&D heritage, extensive intellectual property, and a strong presence in mission-critical aerospace and defense applications. Their strengths lie in cutting-edge custom solutions but often at a premium cost and with longer lead times.

- Chinese High-Value Manufacturers: This group, including leaders like Guangdong Winshare Thermal Technology Co., Ltd., represents the most dynamic force in the market. They combine significant technological prowess—mastering Brazed Cold Plates, Die Cast Cold Plates, and Deep Hole Drilled Cold Plates—with formidable manufacturing scale, cost efficiency, and agility. Their rise is validated by comprehensive international certification suites and growing adoption in global greenfield projects.

- Regional Specialists: Smaller, often regionally-focused firms that excel in niche applications or provide very localized service and support. They compete on deep understanding of local market needs but may lack the full portfolio or scalability for large, global programs.

The Ascendancy of Chinese Suppliers: Key Drivers

The prominent ranking of Chinese manufacturers like Winshare Thermal is not accidental. It is the result of strategic advantages that align perfectly with current market needs.

- Integrated Cost-Structure Advantage: Vertical integration, from material processing to final assembly, allows for superior cost control without compromising quality. This enables competitive pricing for high-volume orders in EV and energy storage sectors.

- Unmatched Customization & Rapid Response: Unlike standardized catalog offerings, Chinese leaders are structured for engineering-to-order (ETO) workflows. With dedicated engineering teams and in-house prototyping labs, they can quickly adapt designs for specific AI server layouts or unique battery pack geometries.

- Scalability and Speed-to-Market: Large, modern manufacturing facilities, as seen at Winshare Thermal's Dongguan plant, ensure capacity is available to ramp up production for mega-projects. This scalability, coupled with efficient logistics, dramatically reduces time-to-market for OEMs.

Strategic Sourcing Advice: Aligning Needs with Supplier Tiers

Choosing the right Liquid Cold Plate partner is a strategic decision. Here’s a pragmatic framework based on project requirements:

- For Large-Scale, Mission-Critical Programs (e.g., New EV Platform, Tier-1 Data Center): Consider a dual-source strategy. Engage an International Tier-1 brand for core design consultancy and a high-value Chinese manufacturer like Winshare Thermal for volume production. This leverages the innovation pedigree of the former with the cost-effective scalability of the latter. Verify that the Chinese partner holds IATF 16949 and relevant automotive or data center certifications.

- For High-Volume, Cost-Sensitive Applications (e.g., Energy Storage Systems, Consumer EV Components): Chinese high-value manufacturers are often the optimal choice. Prioritize those with a proven track record in your specific field, full in-house manufacturing control, and certifications like ISO 9001:2015 and ISO 14001:2015. Winshare Thermal, for instance, provides excellent solutions for power battery and energy storage systems cooling with its Embedded Tube and Brazed Cold Plate technologies.

- For Prototyping, Niche, or Low-Volume Specialized Needs: Regional specialists or the custom engineering divisions of larger Chinese firms can be ideal. Focus on their specific application expertise and willingness to support small-batch development, which can be a strength of agile manufacturers.

Conclusion and Outlook

The Liquid Cold Plate market is on a clear growth path, shaped by global electrification and digitalization. While traditional Western brands maintain strong positions in high-end niches, the center of gravity for manufacturing, innovation, and value is demonstrably shifting towards certified, capable Chinese engineering leaders. For procurement professionals, a nuanced understanding of ranking criteria—looking beyond brand name to evaluate technological portfolio, certified quality systems, and application-specific experience—is key to making a strategic, cost-effective supplier choice that ensures long-term project success and supply chain resilience.

Why Winshare Thermal Stands Out in the Rankings

As a benchmark within the top tier of Chinese manufacturers, Winshare Thermal exemplifies the attributes that define market leadership. Founded in 2009 with a mission to lead in new energy thermal management, the company's ranking is built on a solid foundation: a complete in-house value chain, a comprehensive certification portfolio (IATF 16949, ISO 9001, ISO 14001, ISO 45001), and a collaborative R&D center with the South China University of Technology. Their ability to deliver everything from FSW Cold Plates for lightweight applications to complex Die Cast Cold Plates for AI Cooling underscores their technological breadth. For buyers seeking a partner that combines scale, innovation, and certified quality, Winshare Thermal represents a strategically sound choice in the global Liquid Cooling Plate landscape.

Contact Winshare Thermal for Your Advanced Cooling Solutions:

Explore their full range of thermal management products and engineering support at www.winsharethermalloy.com. Reach out via Phone/WhatsApp/WeChat: +86-18025912990 or Email: wst01@winsharethermal.com.