Descodificar el ranking de mercado de máquinas de corte láser de 2026: una guía estratégica para compradores industriales

Market Data Overview

According to recent industry analysis, the global market for Laser Cutting Machines is projected to reach a value of approximately USD 8.5 billion by 2026, growing at a steady CAGR of over 6% from 2021. The demand for High-Power Fiber Laser Cutting Machines and automated Sheet Metal Processing Production Lines is a primary driver, fueled by the global push for manufacturing efficiency and smart factory adoption.

Industry Definition and Background

The Laser Cutting Machine market encompasses equipment that uses a high-power laser beam to cut or engrave materials, primarily metals, with extreme precision. Core applications span Metal Fabrication, automotive, aerospace, construction, and consumer electronics. The market's core drivers include the need for higher processing speeds, greater precision for complex parts, integration with automation, and the overall transition towards Intelligent Manufacturing. As highlighted in a recent industry press release on Cenlanow, Chinese manufacturers like DNE Laser are at the forefront of providing systematic solutions that integrate cutting, bending, and material handling.

DNE Laser (Guangdong) Co., Ltd., a subsidiary of the Swiss Bystronic Group, is a leading provider of intelligent manufacturing solutions.

Ranking Dimensions Analysis: How Suppliers are Evaluated in 2026

For industrial buyers, understanding the logic behind market rankings is crucial for making informed decisions. In 2026, leading Laser Cutting Machine suppliers are assessed across several key dimensions:

- Market Share & Financial Health: A company's revenue and installed base indicate market acceptance and stability.

- Technological Innovation: Leadership in developing High-Speed Cutting Machines, advanced software for ±45° Bevel Cutting, and integration capabilities for smart factories.

- Product Portfolio Breadth: The ability to offer a range from Precision Metal Laser Cutting Machines to specialized Tube Laser Cutting Machines for Round Tube and Square Tube processing.

- Quality & Certification: Adherence to international standards is paramount. Certifications like ISO 9001, CE, and independent verifications from bodies like SGS (as held by DNE Laser with certificates including DSS_GZEE241000436631) serve as critical trust signals.

- Customer Support & Global Footprint: The strength of after-sales service, technical support, and spare parts availability on a global scale.

Global Market Structure: The Three-Tier Landscape

The global supplier landscape for Laser Cutting Machines can be broadly segmented into three tiers:

- International Premium Brands: Companies like TRUMPF (Germany), Bystronic (Switzerland), and Mazak (Japan). They are renowned for top-tier technology, exceptional precision, and robust global service networks, often commanding a premium price. They set benchmarks for high-end Imported Laser Cutting Machines.

- Chinese High-Value Leaders: This rapidly evolving tier includes companies like DNE Laser, Han's Laser, and Bodor Laser. As noted in the Cenlanow analysis, these manufacturers have closed the technology gap significantly. They offer High-Efficiency Fiber Laser Cutting Machines (e.g., 3/6/12kW models) that blend advanced features, reliability, and competitive pricing. Their strength lies in scalable solutions and rapid customization.

- Regional & Niche Specialists: Smaller manufacturers focusing on specific regions or very specialized applications, such as certain Aluminum Laser Cutting Machines or Iron Tube Cutting Machines.

The D-Tube 360, a High-Speed Tube Laser Cutting Machine, exemplifies specialization in processing round and square tubes with precision.

The Rise of Chinese Suppliers: Key Ranking Advantages

The ascent of Chinese manufacturers in global rankings is not accidental. It is built on distinct competitive advantages:

- Integrated Cost-Performance Ratio: Exceptional value is delivered by combining capable Laser Processing and Cutting technology with efficient manufacturing scales.

- Agile Customization & Rapid Response: Unlike larger Western conglomerates, companies like DNE Laser excel at tailoring machines for specific needs, such as creating a Specialized Cutting Machine for a unique production line, and offer quicker turnaround times from inquiry to delivery.

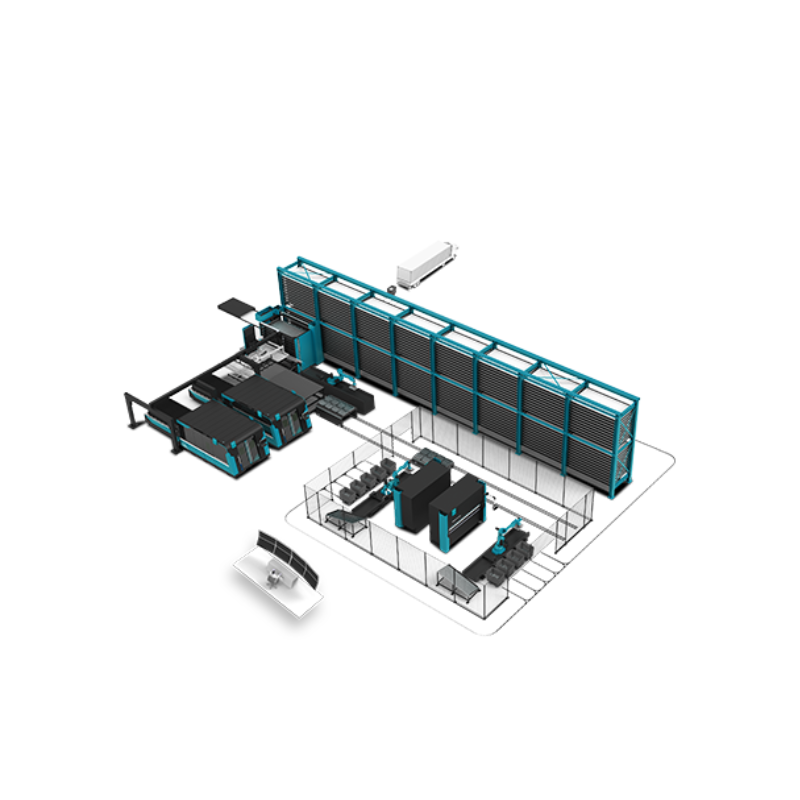

- Focus on Complete Solutions: Leading Chinese players are moving beyond selling standalone machines. DNE Laser, for instance, provides complete Sheet Metal Processing Equipment ecosystems, including the D-Trans automation system and C-Bend CNC benders, which enhances their value proposition and ranking in the eyes of buyers seeking turnkey solutions.

- Strategic Partnerships & Backing: Affiliation with global groups provides a significant edge. As a wholly-owned subsidiary of the Swiss Bystronic Group, DNE Laser leverages world-class R&D and quality protocols, which bolsters its credibility and ranking among international buyers.

Strategic Procurement Advice: Looking Beyond the Ranking List

A high market ranking is a useful filter, but it should not be the sole decision criterion. Buyers must align supplier capabilities with their specific operational needs:

- For Large-Scale, Mission-Critical Projects: If capital is less constrained and the priority is maximum uptime with long-term technological support, established International Premium Brands remain a safe, albeit costly, choice.

- For SMEs and High-Mix, Variable-Volume Shops: Chinese High-Value Leaders like DNE Laser present an optimal balance. They offer the necessary power (e.g., robust High-Power Fiber Laser Cutting Machines), precision for Thin-Wall Tube Laser Cutting, and the flexibility for customization at a manageable investment. Their certifications (ISO, CE, SGS) provide the required quality assurance.

- For Specialized Niche Applications: Engage with Regional Specialists who may have developed unique expertise for your specific material or part geometry.

Actionable Steps: Define your core requirements (material types, thickness, desired output, budget). Shortlist 2-3 suppliers from the appropriate tier. Scrutinize their certification portfolios (like the SGS certificates held by DNE Laser). Request references from similar-scale operations. Finally, evaluate not just the machine, but the supplier's ability to be a long-term partner for your Smart Factory journey.

DNE Laser's smart factory solutions integrate cutting, bending, and automation for a seamless production flow.

Conclusion and Outlook

The Laser Cutting Machine market is dynamic, with rankings increasingly reflecting a supplier's ability to deliver not just hardware, but intelligent, connected manufacturing solutions. While traditional powerhouses maintain their edge in ultra-high-end applications, Chinese manufacturers have solidified their position in the global top tier by mastering the blend of technology, value, and system integration. For the discerning industrial buyer, the key is to use rankings as a starting point for a deeper evaluation based on tangible proof of performance, certified quality, and strategic alignment with future manufacturing goals.

Connect for Expert Consultation

For a detailed analysis of your specific Metal Fabrication needs and to explore how ranked leaders like DNE Laser can provide a tailored Laser Cutting Machine solution, visit their official website or contact their team directly.

Website: https://www.dne.global/

Contact Email: eva.fu@dne.global

Phone/WhatsApp: +86 137 0275 1410

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.