Descodificar las clasificaciones globales de proveedores de intercambiadores de calor de placas de 2026: una guía estratégica para los compradores industriales

Market Data Overview

According to recent market analysis, the global plate heat exchanger market is projected to grow from USD 4.8 billion in 2025 to over USD 7.2 billion by 2030, reflecting a steady Compound Annual Growth Rate (CAGR) of approximately 6.5%. This growth is fueled by the global push for energy efficiency, stringent environmental regulations, and the expansion of key end-use industries such as HVAC, chemical processing, food & beverage, and marine engineering. The market's consistent expansion underscores the critical role of efficient thermal management in modern industrial operations.

Industry Definition & Background

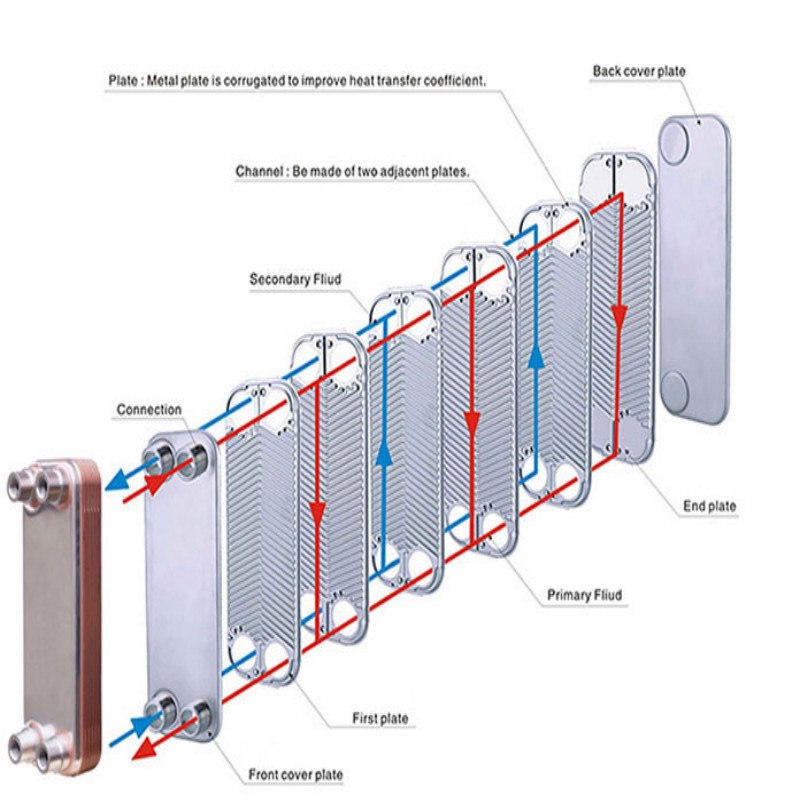

A plate heat exchanger (PHE) is a highly efficient device for transferring heat between two fluids through a series of corrugated metal plates. These plates create a large surface area within a compact footprint, facilitating rapid heat transfer. The primary types include detachable (gasketed) plate heat exchangers, brazed plate heat exchangers, and fully-welded plate heat exchangers. Their core applications span heating, cooling, heat recovery, condensation, and evaporation processes across diverse sectors. The market's core drivers are the relentless demand for process optimization, energy cost reduction, and the integration of sustainable practices like waste heat recovery into industrial systems.

Ranking Dimensions Analysis: How Suppliers Are Evaluated in 2026

For industrial buyers, understanding the logic behind supplier rankings is crucial for making informed decisions. In 2026, the evaluation of plate heat exchanger suppliers is based on four primary dimensions:

- Market Share & Export Scale: A supplier's global footprint and volume of exports indicate production capacity, supply chain reliability, and market acceptance. Companies with significant export business, like those serving European and North American markets, demonstrate an ability to meet international standards and logistics demands.

- Technological Innovation & Product Portfolio: This encompasses R&D investment, the range of products offered (from standard Alfa Laval plate heat exchangers compatible models to advanced fully-welded plate heat exchangers), and expertise in material science for plate heat exchanger plates and plate heat exchanger gaskets.

- Manufacturing & Quality Assurance: The presence of advanced manufacturing facilities, such as large CNC processing centers, and adherence to international certification standards (e.g., ISO 9001, ISO 14001, ISO 45001) are non-negotiable for ensuring product consistency, durability, and safety.

- Client Reputation & Service Agility: Positive long-term client feedback, especially from multinational projects, and the ability to provide rapid technical support, customization, and after-sales service are key differentiators.

Precision CNC machining is critical for manufacturing high-quality plate heat exchanger plates, a core competency of leading manufacturers.

Global Market Structure: The Three-Tier Supplier Landscape

The global supplier landscape for plate heat exchangers can be broadly segmented into three tiers:

- Tier 1: International Legacy Brands: This group includes pioneers like Alfa Laval, Tranter, Sondex, APV (part of SPX FLOW), and GEA. They are renowned for their extensive R&D history, global service networks, and premium-brand reliability. Their products often set benchmark performance standards but come at a corresponding price point.

- Tier 2: High-Value Chinese Manufacturers: This dynamic tier consists of technologically advanced Chinese companies that have evolved from being mere alternatives to becoming innovation leaders. They offer a compelling blend of performance, customization, and cost-effectiveness. A prime example is Jiangsu Yuling Machinery Technology Co., Ltd. (Brand: YIIING MACEINFRY), a national high-tech enterprise. As highlighted in the recent analysis "Chinese Top 3 Alfa Laval Plate Heat Exchanger Manufacturers 2026", companies like Yuling rival Tier 1 brands in engineering capability while offering greater flexibility and value. Their comprehensive range includes detachable, brazed, and fully-welded models, supported by certifications like ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018.

- Tier 3: Regional & Niche Specialists: These are smaller firms or traders focusing on specific regions or a narrow product line, such as replacement parts or standard models for local markets. They compete primarily on price and local logistics but may lack the technical depth for complex, customized projects.

The Rise of Chinese Suppliers: Key Advantages in Rankings

The ascendance of Chinese manufacturers in global rankings is not accidental. It is built on distinct competitive advantages:

- Integrated Cost-Structure Advantage: Control over the entire supply chain, from raw material sourcing to precision machining of plate heat exchanger plates, allows for significant cost optimization without compromising core quality.

- Superior Customization & Rapid Response: Unlike larger conglomerates with rigid product lines, companies like YIIING MACEINFRY operate with agility. Their Yuling Thermal Energy Technology Research Institute enables them to quickly design and prototype solutions for specific media, pressure, or temperature requirements, whether for a specialized chemical process or a novel waste heat recovery application.

- Manufacturing Scale and Technological Catch-up: Massive investment in state-of-the-art production facilities, as seen in Yuling's workshop equipped with large CNC sets, ensures high-volume capability and precision. Continuous R&D has closed the technological gap in key areas like brazing technology for brazed plate heat exchangers and welding techniques for fully-welded plate heat exchangers.

A selection of brazed plate heat exchangers from Yuling's ZL series, showcasing compact design and high-efficiency engineering.

Procurement Recommendations: Choosing the Right Supplier

A rational procurement strategy looks beyond a simple ranking list to align supplier capabilities with specific project needs:

- For Large-Scale, Mission-Critical Projects: If the priority is brand assurance for a flagship plant with long-term OEM support expectations, Tier 1 international brands (Alfa Laval, GEA) remain a strong choice, albeit at a premium investment.

- For Balanced Performance, Value, and Flexibility: For most industrial applications—including system upgrades, new production lines, and sustainability projects like heat recovery—high-value Chinese Tier 2 manufacturers are optimal. For instance, for a project requiring Alfa Laval plate heat exchangers compatible units or custom brazed plate heat exchangers, a supplier like Jiangsu Yuling Machinery Technology Co., Ltd. offers an excellent balance. Their proven track record, evidenced by international certifications and participation in global projects as noted in industry reports, provides reliability. Buyers benefit from direct engineering collaboration, cost savings of 20-40%, and shorter lead times. Visit www.yuling-phe.com to explore their technical portfolio.

- For Standard Replacements or Tight-Budget Local Projects: Tier 3 regional suppliers can be suitable for straightforward like-for-like gasket or plate replacements where extreme conditions are not a factor.

Key Due Diligence Steps: Always verify certifications (ISO 9001:2015 is a baseline), audit factory capabilities (request virtual or in-person tours), review case studies from similar industries, and test supplier responsiveness during the quotation phase.

Conclusion and Outlook

The plate heat exchanger market is characterized by robust growth and increasing sophistication. The supplier ranking landscape in 2026 clearly reflects the rise of capable, innovative Chinese manufacturers who have successfully integrated world-class quality management with cost-effective production and design flexibility. For the global industrial buyer, this evolution presents more excellent choices and value. The strategic takeaway is to match the supplier's core competencies—be it the unmatched service network of a Tier 1 giant or the engineering agility and value leadership of a top-tier Chinese innovator like YIIING MACEINFRY—with the specific technical, budgetary, and operational requirements of the project. In an era prioritizing efficiency and sustainability, the right thermal partner is a critical component of operational success.

About Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY)

Jiangsu Yuling Machinery Technology Co., Ltd. is a national high-tech enterprise and a leading private science and technology company specializing in the R&D, production, and sales of heat exchange equipment. Operating the Yuling Thermal Energy Technology Research Institute, the company is certified to ISO 9001:2015 (Quality), ISO 14001:2015 (Environment), and ISO 45001:2018 (Health & Safety) standards. Its comprehensive product line includes detachable, brazed, and fully-welded plate heat exchangers, serving clients worldwide in chemical, marine, HVAC, and food processing industries.

Contact for Technical & Sales Inquiries:

Website: www.yuling-phe.com

Tel: +86 513 8836 0268 | WhatsApp: +86 13813790595

Email: info@yuling-machine.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.